What are the biggest advantages of thermoplastic materials :?

- no residual monomer

- no metal parts

- flexibility - aesthetics

- low weight

Due to their chemical composition, thermoplastics are divided into:

- polyamides

- polymers, copolymers

- PEEK

- acetals

- nylons

Polyamides and polymers exhibit an optimal combination of stiffness and flexibility, making them ideal for partial and full dentures. Due to high translucency and transparency, dentures made of these materials are aesthetic and look good in the oral cavity.

PEEK, lightweight, hypoallergenic material for skeletal dentures, primary and secondary telescopic crowns as well as frameworks for veneering with a composite of hardness and density similar to real bone. PEEK is currently the most biocompatible thermoplastic for use in dental prosthetics

Acetal and nylon are older thermoplastic materials with high flexibility. The biggest disadvantage of these materials is water absorption, which leads to rapid discoloration and unsightly appearance.

iPress injection molding machine for thermoplastic materials with a starter kit (can, insulator and material for 30 dentures)

The latest injection system using technology developed by Dental Flex Italia®, maximizing efficiency, safety and significantly reducing investment costs.

The iPress injection molding machine control panel has been designed in a user-readable way. Two large displays facilitate visual control of the parameters of the set program from anywhere in the workshop. Each button has only one function, making operation of the device very simple and intuitive. The iPress injection molding machine operates fully automatically. After completing the heating cycle, the cartridge is crushed by the device without the intervention of a technician, and operation of compressed air from the compressor ensures stable quality of each injection. The device heats the can itself during injection - the can does not require prior heating in a stove or a water bath. It is placed on the device at the beginning of the heating cycle and acquires the appropriate temperature together with the material, which allows for repeatable quality and homogeneous injected dentures, making them easier to process and polish to a shine. The small dimensions allow the device to be placed anywhere in the workshop, and the installation process only requires connecting electricity and compressed air.

The biggest advantages of the iPress injection molding machine

- Pneumatic - compressed air ensures stable injection quality in each injected prosthesis. Possibility to work with pressure up to 9 Bar.

- Automatic - after the heating cycle is completed, the cartridge will be crushed automatically by the device without the intervention of a technician.

- The strong piston crushes the cartridge with a force of 650 kg, which ensures perfect quality of the final injection. The homogeneously injected material is easier to process and polish to a shine.

- It heats the can during injection - the can does not require prior heating. It is placed in the device at the beginning of the heating cycle and acquires the appropriate temperature together with the material.

- Compact and easy to install - small dimensions allow the device to be placed anywhere in the workshop, and the installation process only requires connecting electricity and compressed air.

Dental Flex Italia, in addition to the iPress injection molding machine, also offers thermoplastic materials for partial and complete dentures Viva Flex Partials and a biocompatible material for the frames of removable dentures PEEK Biossis. Their physical and chemical properties allow the work to eliminate: - metal retention elements, - make it possible to perform partial and complete works, - completely free of harmful residual monomer,

By investing in the iPress system, in addition to a solid and modern device for pressing thermoplastic materials, you receive substantive and marketing support in the form of leaflets for patients, thanks to which you will interest potential customers in your new product.

Device parameters

- Automatic.

- Injection force 650 kg.

- Dimensions: 16 cm x 21 cm x 49 cm (h).

- Weight 13 kg.

- Power supply 230V.

- Working pressure 7-8 Bar.

- Temperature max 400 °C.

- Piston diameter 25 mm.

Packaging:

- 1pcs device

- Starter kit (can, insulator, and material for 30 dentures)

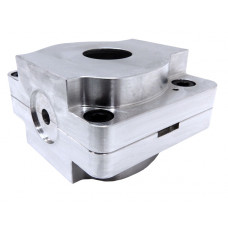

Can for iPress injection molding machine

Very strong can, milled from one aluminum block.

Parameters:

- Allen key for loosening or tightening screws.

- 4 mounting screws.

- Size 15.5x8x12cm (length x width x height).

- Weight 1.6 kg.

Packaging:

- 1 pc can.

- 1pcs Allen key.

Aluminum tubes 22mm/90mm 30 pieces

Empty aluminum tubes with caps for injection of thermoplastic materials.

- Diameter 22mm

- Height 90 mm

Packaging:

- 30 pcs

Aluminum tubes 22mm/120mm 30 pieces

Empty aluminum tubes with caps for injection of thermoplastic materials.

- Diameter 22mm

- Height 120 mm

Packaging:

- 30 pcs

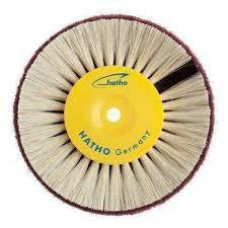

Hatho - brush 80mm white hard bristles + fleece

Hatho - brush 80mm white hard bristles + fleece. For thermoplastics and acrylic.

Package:

1 piece.

4Shine Polishing paste 250g - NEW

Polishing paste for polishing to a mirror shine: acrylics, thermoplastics and metals.

Packaging:

- 250 g

Viva Flex "XR" - size XXL 22mm rigid, chemically bonded to acrylic

Viva Flex "XR" is a modern polymer-based thermoplastic material for universal use. Increased hardness compared to other thermoplastic materials allows the production of complete and partial dentures with pelottes as well as overdentures or partial dentures with clasps. It chemically combines with acrylate resins for "S" repairs, so the material can be repaired and relined in a traditional way.

Viva Flex "XR" is offered in ready-made cartridges with a diameter of 22 mm and 25 mm and in collective packages of 500 grams in the color XR1-SP.

Advantages:

- The material is chemically combined with acrylate resins for repairs.

- Melting point: 305°C.

- Melting time: 15 minutes.

Packaging:

- 1 piece

4SHINE Polishing Powder 10kg

- The new line of 4Shine Polishing Powder products

Everall7 is pleased to present a new line of auxiliary products for the pre-polishing of 4Shine Polishing Powder acrylic and thermoplastics. Thanks to the support of Polish dental technicians, we have created two variants of abrasion: regular - medium abrasive and hard - highly abrasive. Our polishing powder is perfect for pre-polishing and shining of all acrylic and thermoplastic materials.

The varied size and sharp contour of the grains allows easier and faster polishing to a high gloss without the need to use silicone rubbers. Thanks to the use of a preservative, it prevents the multiplication of bacteria and fungi during use to ensure greater comfort of work.

Package:

- 10 kg

Unitrim stone for thermoplastics / acetal large EVE

Highly abrasive stone which, thanks to its porous structure, does not heat up the thermoplastic material during processing, reducing the risk of material deformation. Use the stone for pre-treatment - collecting material. (use 3000-5000 rpm optimally / max 20,000 rpm)

Package :

1 piece.

Chamois leather with pumice stone 22mm orange (1 step) EVE

Orange chamois soaked in pumice.

Use an orange chamois leather to smooth the surface and prepare it for gloss polishing of acrylic, acetal, nylon and all thermoplastics. Deerskin is already soaked in pumice - do not use additional pastes and preparations. (use 5,000-7,000 rpm optimally / 10,000 rpm maximum)

For the best effect, use an orange chamois and then a pink chamois - kod_mikran: 2243

package:

1 piece 22 mm / 3mm

Chamois leather with pumice stone 22mm pink (2nd step) - EVE

Characteristic:

Pink chamois soaked in pumice.

After using an orange chamois, use a pink chamois for a high gloss finish for acrylic, acetal, nylon and other thermoplastics. Deerskin is already soaked in pumice - do not use additional pastes and preparations. (use 5,000-7,000 rpm optimally / 10,000 rpm maximum)

For best results, use an orange chamois and then a pink chamois.

Package:

1 piece 22 mm / 3mm

Viva Flex "Gingiva" - size XL, diameter 22mm, opaque

One of the most universal materials for use by a dental technician.

Viva Flex Partials Gingiva is a perfectly composed material for any type of partial denture, guaranteeing the right balance between flexibility and stiffness. Extremely easy to process, polish to a high gloss and resistant to discoloration. Working with the Viva FLex Partials Gingiva material does not require expansion plaster.

Application:

- Partial dentures with pelottes,

- Complete dentures,

- Clips and space maintainers,

- Aesthetic clasps for skeletal dentures,

Viva Flex Partials GINGIVA material is characterized by no veins and low translucency

Characteristics:

- Very low shrinkage 0.65%

- Low fluid absorption - 0.3%

- Injection on 3rd class plaster,

- No residual monomer

- Easy to process and polish

- Easy to repair, (post-injection)

- Increased resistance to damage,

- Lightly veined

Available packaging:

- XL - 23 grams

- Cartridges with a diameter of 22 mm and 25 mm

Advantages:

- Aesthetics - the smooth and mirror surface of the denture reduces fluid absorption and plaque deposition, as well as the absence of discoloration and unpleasant odor.

- Comfort - high-quality material guarantees a perfect fit of the denture in the oral cavity.

- Functionality - perfect balance between stiffness and flexibility

Packaging:

- 1 piece.

Viva Flex "Gingiva" - size XL, diameter 25 mm, opaque

One of the most universal materials for use by a dental technician.

Viva Flex Partials LF is a perfectly composed material for any type of partial denture, guaranteeing the right balance between flexibility and stiffness. Extremely easy to process, polish to a high gloss and resistant to discoloration. Working with Viva FLex Partials LF does not require expansion plaster.

Application:

- Partial dentures with pelottes,

- Complete dentures,

- Clips and space maintainers,

- Aesthetic clasps for skeletal dentures,

Viva Flex Partials GINGIVA is characterized by no veins and low translucency

Characteristics:

- Very low shrinkage 0.65%

- Low fluid absorption - 0.3%

- Injection on 3rd class plaster,

- No residual monomer

- Easy to process and polish

- Easy to repair, (post-injection)

- Increased resistance to damage,

- Lightly veined

Available packaging:

- XL - 23 grams

- Cartridges with a diameter of 22 mm and 25 mm

Advantages:

- Aesthetics - the smooth and mirror surface of the denture reduces fluid absorption and plaque deposition, as well as the absence of discoloration and unpleasant odor.

- Comfort - high-quality material guarantees a perfect fit of the denture in the oral cavity.

- Functionality - perfect balance between stiffness and flexibility

Packaging:

- 1 piece

Hatho - PoliStar pink paste 150g

Hatho - PoliStar pink paste 150g. For thermoplastics and acrylics.

Packaging:

- 1 piece

PoliStar Creme Hatho - high gloss paste 90 gr

Hatho - PoliStar TUBA paste high gloss 90 gr.

- For thermoplastic materials and acrylic.

Packaging:

- 1 piece

Hatho - soft green silicone cotton brush

Hatho - brush soft green silicone cotton. For thermoplastics and acrylic.

Package:

1 piece

Villacryl Thermo Iso-clear light-curing insulator 30ml

Villacryl Thermo Iso-clear High temperature resistant light-curing insulator. Perfect for all types of thermoplastics.

Package:

- 30 ml.

Thermo Flexi-J Primer 30 ml

Thermo Flexi-J Primer. Primer combining thermoplastic materials based on polyamides. Useful for re-injecting buckles, repairs or relining.

Packaging:

- 30ml.

Villacryl Thermo Multi Spray 400ml

Universal grease for cans, cartridges and aluminum tubes. The material, whose production uses high-quality raw materials without solvents, is available in a convenient aerosol.

Advantages:

High temperature resistant, Villacryl Thermo Multi Spray can be used as a release agent for all types of injection molding machines injecting thermoplastic materials for dentures.

It is perfect as a lubricant used for cartridges and aluminum tubes filled with thermoplastic material immediately before the injection process.

After spraying, it creates a thin, high-temperature-resistant slip layer on the surface, ensuring protection of the injection molding machine's heating chamber against seizure. By using it, the chances of a trouble-free injection process increase.

It does not contain solvents and does not leave any residues in the heating chamber, making it suitable for all types of injection molding machines.

Additionally, it can be used as an agent that increases the life of injection or polymerization cans, insulates surfaces from plaster and preserves them to prevent rusting or tarnishing.

Packaging:

- Spray capacity 400 ml

Gumki do nylonu i materiałów termoplastycznych.

Bardzo wysokiej jakości gumka do polerowania nylonu. Doskonała jakość spoiwa pozwala na bardzo wydajną pracę . Prędkość maksymalna 12000 obrotów na minutę.

Opakowanie:

- 1szt

Hatho - Lintygrey polishing paste 90gr (gray)

Hatho - Lintygrey polishing paste 90 gr (gray). For thermoplastics and acrylic.

Package:

1 piece

Hatho - cotton shield 4x50 (100mm) muslin

Cotton disc 4x50 (100mm) muslin. For polishing thermoplastic materials and acrylic.

Package:

1 piece

Gypsum class IV. Marble Stone Evolution - expansion gypsum in pressure injection processes 3kg

Special double-expansion plaster for duplicating models.

Characteristic:

- White color.

- It does not require the use of a special liquid, mixed with demineralized water.

- Dedicated to work with devices injecting thermoplastic materials.

Packaging:

- 3kg

Izolator Gyplux

Charakterystyka:

- Lakier stosowany na powielony model gipsowy, zapewnia idealnie gładką i błyszczącą powierzchnię do śluzówkową w protezach acetalowych, nylonowych, oraz w innych protezach z tworzyw termoplastycznych.

- Polimeryzuje pod wpływem światła UV)

Opakowanie:

- 30ml , lub 50ml

Acetal Dental 500 g

ACETAL DENTAL - jest materiałem nietoksycznym i nie wywołuje alergii.

Stanowi odpowiednie zastępstwo dla żywicy akrylowej i metalu w wielu pracach protetycznych.

Zastosowanie acetalu:

klamry estetyczne do protez tzw. szkieletowych,

protezy częściowe,

mosty i mosty na teleskopy,

elementy protetyczne na implantach,

szyny nagryzowe i stabilizujące,

elementy retencyjne na belkach stanowiące jednocześnie wzmocnienie.

Dane techniczne:

- Temperatura wtrysku - 220 °C

- Czas topienia materiału - 20min

- Wtrysk i podgrzewanie - 2-3 min

- Czas chłodzenia pod stałym ciśnieniem - 20-40 min

- Ciśnienie robocze - 4,0 Bary

Opakowanie:

- 500 g

Acetal - polymerization can type J100

Universal box for standard work for the J 100 injection molding machine.

Package:

- 1 piece.

Metal cork for nylon

Injection cartridge closing plug with nylon material prevents material from flowing into the device.

Package:

1 piece.

Walce aluminiowe z korkami J100 - 22mm

Aluminiowe, jednorazowe łuski o średnicy 22mm z korkami teflonowymi do wtryskarek.

Opakowanie:

- 1 sztuka walec + 1 korek

Acetal - Izolator silikonowy - Tube Lubricant

Charakterystyka:

- Izolator silikonowy do prac w wysokiej temperaturze.

- Tylko do urządzeń : ACTIO, J-100, J-200

Opakowanie:

- 50 ml (cc)

Pasta polerska do acetalu i akrylu

Uniwersalna pasta polerska do acetalu i akrylu.

Opakowanie:

- 50 ml

FJP Thermoplastic resin color B

The new thermoplastic resin is an alternative to commonly used materials from the group of polyamides or "nylons" such as: "Valplast", "Flexite", "Flexi J". Dental prostheses made of these materials are famous for their high aesthetics and recognition among patients who use such prostheses. Traditional polyamides, apart from their undoubted advantages, also have disadvantages that make it difficult to process and keep clean dentures made of them. Many years of research into the improvement of nylon materials have led to the creation of a new material devoid of these drawbacks.

Pressing Dental's material, FJP has the following features:

- slightly flexible, making it very easy to process using traditional methods and tools. Reduced flexibility has a positive effect on the prosthetic base, does not cause trauma related to the use of a flexible denture

- translucent, thanks to which it perfectly blends with the patient's mucosa, making the used prosthesis imperceptible in the mouth

- unlike traditional nylons, it almost does not absorb water (only 1/3 of traditional nylon), which significantly extends the life of dentures

- has very good color stability, does not discolor during use

- precision ensures very good adhesion to the substrate

- does not deform

- it can be sterilized at 120 ° C

- does not create air bubbles even with very thin elements

- it does not need to be drained before injection.

- easy to work with, can be well polished

- bonds chemically with acrylic using glue

- it can be repaired and reworked

- once remelted, it can be injected a second time (40-50% should be added to the new material) without losing its mechanical and physical properties.

Package:

- 250 g.

MaxiFresh cleaning tablets 24 pieces

MaxiFresh cleaning tablets.

- For professional and home cleaning and care of whitening splints, retainers, relaxation splints, bruxism splints and splints for athletes, thermoplastic materials and trainers.

Advantages:

- Reduces discoloration.

- Refreshes the surface and eliminates unpleasant odors.

- Saves material because it does not contain abrasive materials.

- Increased durability of the dental splint with daily cleaning.

Use:

- Place the Maxi-Fresh cleaning tablet in a vessel filled with 150 ml of water and a temperature of approximately 37C.

- (Cooler water may prolong the tablet dissolution process).

- Once the tablet has completely dissolved, place the splint in a container for a minimum of 45 minutes.

- After completing the cleaning process, wash the rail under running water and dry the surface.

Packaging:

- 24 pcs.

Walce aluminiowe (22mm)

Aluminiowe, jednorazowe łuski, bez korków średnica 22 mm ,do wtryskarek.

Opakowanie:

- 1szt.

Walce MAXI z korkami 25mm

Aluminiowe, jednorazowe łuski o powiększonej średnicy (25mm) z korkami teflonowymi do wtryskarek

Opakowanie:

- 1sztuka walec + 1 sztuka korek.

Corflex - polishing liquid

Aromatic liquid for polishing rails and protectors made of CORFLEX and other thermoplastics and acrylic. Apply a small amount of the aromatic liquid to the work surface, before handing it over to the patient. It gives a pleasant mint flavor and aroma and adds shine.

Package:

30 ml.

Acetal Acecril acetal / acrylic glue

Application:

- Adhesive providing a chemical bond between acetal and acrylic.

- Strengthens and improves the maintenance of acrylic saddles in acetal skeletal dentures.

- It prevents the acrylic from peeling off (sticking out) from the acetal surface and the accumulation of food debris in the denture.

- Do not use on acrylic teeth, the adhesive is only applicable for acrylic monomer-polymer.

Package:

- Component A: 10ml + Component B: 8ml

Acetal-can type 200

Acetal type 200 can Injection and polymerization of all acrylic resins

Thanks to the 200-type can, two dentures can be made and polymerized simultaneously in record time in just 30 minutes

Package:

1 piece.

Villacryl Thermo Press 250g

Villacryl Thermo Press is a polyamide-based thermoplastic. It is dedicated to all settling dentures, such as: full dentures, partial dentures, micro dentures, as well as retention elements in skeletal dentures, retention splints and space maintainers.

Description:

- Microcrystalline structure

- Working on a 4th grade plaster model

- No residual MMA monomer

- Available colors 0, T2, T3, T4

Advantages:

- Easy processing and polishing

- Low absorption of fluids from the oral cavity

- Optimal flexibility and hardness of the prosthesis

- Biocompatible dyes

- Possibility to use most injection molding machines available on the market

Technical data:

*According to EN ISO 20795-1:2013 "Dentistry - Polymers for base plates - Part 1: Polymers for base plates of dentures" (technical data)

- Injection temperature 275-285 °C

- Melting time 15-24 min. ( Small cartridge 15 min. Medium cartridge 20 min. Large cartridge 24 min.)

- Injection pressure 6.0-9.0 bar

- Pressure holding time approx. 3 min.

- Cooling time minimum 15 minutes.

Packaging:

- 250g

Opaska pierścienia bakielitowego A-20/II

Mosiężna opaska chroniąca pierścień bakelitowy przed pękaniem.

Opakowanie:

- 1szt

Silicone spray for injection molding machines

Aerosol silicone to lubricate the cartridge before inserting it into the injection molding machine. Reduces friction during injection.

Packaging: 400 ml

Tubes 22mm with a cap

Empty tubes with a cap for injection of thermoplastic materials.

Data:

Diameter 22mm.

Size M and L

Package:

1pc tube

1pc cap

* Set for polishing thermoplastic materials EVE - PROMOTION

A complete kit needed for processing and polishing thermoplastic materials (polymers) to a high gloss. Also recommended for edging and polishing traditional acrylic.

Includes:

Step 1:

- Unitrimm Stone - 1x Highly abrasive stone which, thanks to its porous structure, does not heat the thermoplastic material during processing, reducing the risk of deformation of the material. Use the stone for pre-treatment - collecting material. (use 3000-5000 rpm optimally / max 20,000 rpm)

Step 2:

- Silicone rubber bands - 3x Classic silicone rubber bands prepare the surface of the thermoplastic material for further polishing. They smooth the surface. (use 5,000-7,000 rpm optimally / 15,000 rpm maximum)

Step 3:

- Orange chamois soaked in pumice - 1x Use an orange chamois leather to smooth the surface and prepare for gloss polishing. Deerskin is already soaked in pumice - do not use additional pastes and preparations. (use 5,000-7,000 rpm optimally / 10,000 rpm maximum)

Step 4:

- Pink chamois soaked with pumice - 1x After using an orange chamois, use a pink chamois for a high gloss. Deerskin is already soaked in pumice - do not use additional pastes and preparations. The shining properties of the pumice stone and the delicate structure of the fabric give the thermoplastic material a high gloss, even after a short treatment. (use 5,000-7,000 rpm optimally / 10,000 rpm maximum)

Package:

1 set

Unitrim stone for thermoplastics / acetal small

Characteristic:

Highly abrasive stone which, thanks to its porous structure, does not heat up the thermoplastic material during processing, reducing the risk of material deformation. Use the stone for pre-treatment - collecting material. (use 3000-5000 rpm optimally / max 20,000 rpm)

Package :

1 piece.

Hatho- zestaw do polerowania tworzyw termoplastycznych Promocja

HATHO stworzyło zestaw do polerowania w tworzywach termoplastycznych. Jest to proces trójstopniowy, wynik polerowania jest znacznie szybszy w porównaniu z istniejącymi metodami. Przy użyciu produktów HATHO ThermoPol Set można w łatwy sposób wypolerować protezy z tworzywa termoplastycznego na wysoki połysk.

Zestaw do polerowania w tworzywach termoplastycznych jest podzielony na trzy etapy:

Wstępne polerowanie. Zamocować szczotkę 80 mm białe twarde włosie + włóknina scotch brite (nr. kat. 4280) na polerce i ustawić prędkość na 1800 obr/min. Użyć pasty szarej (nr. kat. 313168) i nacierać nią szczotkę przez 2 sekundy. Polerować wybraną powierzchnię około 3-4 minuty do wygładzenia.

Czyszczenie, polerowanie na połysk. Zamocować miękką silikonową bawełnianą szczotkę 14 warstwową do polerowania (nr. kat. 869 100/14) na polerce i ustawić prędkość na 1800 obr/min. Nanieść odpowiednią ilość kremu (nr. kat. 313200) zalecane 0,5 na protezę. Polerować około 3-4 minut, aż do wygładzenia pod ostateczne polerowanie.

Polerowanie na ostateczny lustrzany połysk. Zamocować impregnowaną muslinową tarczę bawełnianą (nr. kat. 868 4" x 50 H) na polerce i ustawić prędkość na 1800 obr/min. Użyć różowej pasty o najdrobniejszej ziarnistości (nr. kat. 313196) i nacierać nią tarczę bawełnianą przez 2 sekundy. Lekko i łagodnie polerować około 3-4 minuty do osiągnięcia ostatecznego lustrzanego połysku na powierzchni protezy.

Zestaw składa się z następujących produktów:

Szczotki 80 mm białe twarde włosie + zdzierna włóknina scotch brite. Zamontowana na plastikowej piaście pozwalającej pracować na mokro jak i na sucho. Dwa rzędy włosia przedzielone warstwą scotch brite. Przeznaczona do pracy na max. obrotach 3,500 obr/min. Profesjonalna szczotka do protez akrylowych (PMMA), termoplastycznych (nylonowych), 3D (akrylowe tworzenie prototypów), materiałów światłoutwardzalnych. Nr. katalogowy 4280.

Pasta polerska PoliStar. Najwyższej jakości, profesjonalna pasta polerska marki PoliStar / Hatho.Konsystencja pasty pozwala idealnie pracować z nią na narzędziach rotacyjnych polerskich. Pasta przeznaczona do polerowania protez akrylowych (PMMA), termoplastycznych (nylonowych), materiałów światłoutwardzalnych. Nr. katalogowy 313168 (90g).

Miękka szczotka do polerowania, stworzona z 14 drobnych warstw silikonowej bawełny zamontowana na plastiku. Przeznaczona do pracy na max. obrotach 3,500 obr/min. Do polerowania protez akrylowych (PMMA), termoplastycznych (nylonowych), materiałów światłoutwardzalnych, tytanu, szlachetnych i nieszlachetnych stopów metali. Nr. katalogowy 869 100/14.

Krem HATHO PoliStar najwyższej jakości krem wypełniony drobnoziarnistym grysem nadający wysoki połysk. Do polerowania protez akrylowych (PMMA), termoplastycznych (nylonowych), 3D w akrylu, materiałów światłoutwardzalnych oraz stopów metali szlachetnych. Wolne od środków powierzchniowo czynnych i rozpuszczalników. Nr. katalogowy 313200. - Tarcza bawełniana 4x50 (100mm). Najwyższej jakości tarcza polerska muslinowa marki HATHO. Przeznaczona do pracy na max. obrotach 3,500 obr/min. Używana do polerowania na wysoki połysk protez akrylowych (PMMA), termoplastycznych (nylonowych), 3D w akrylu, materiałów światłoutwardzalnych, chromu, kobaltu, tytanu, stali nierdzewnej, aluminium i innych stopów nieszlachetnych. Nr. katalogowy 868 4 " x 50 H.

Profesjonalna różowa pasta polerska do polerowania na ostateczny połysk o najdrobniejszej ziarnistości, przeznaczona do protez akrylowych (PMMA), termoplastycznych (nylonowych), 3D w akrylu, materiałów światłoutwardzalnych. Nr. katalogowy 313196.

Opakowanie:

- 1 zestaw