3D printers for orthodontics, prosthetics and implantology created by the world leader, Formlabs.

We are an authorized distributor of Formlabs, contact us if you are interested in 3D printing technology and are looking for professional advice. Our specialists in 3D printing will certainly be able to help you make the choice that suits the specifics of your work.

Formlabs Work platform for Form 4

The Form 4 work platform has a durable aluminum surface. A spare platform can speed up your workflow and allow for uninterrupted printing, whether you're changing resins or starting a new print.

Packaging:

- 1 piece

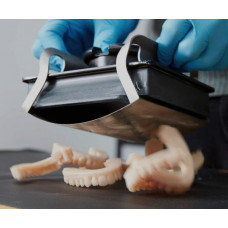

Formlabs Form 4 Finish Kit

Finish your prints quickly and easily with the versatile Form 4 Finishing Kit to keep your workspace clean and tidy. Includes two rinsing containers, rinsing basket, resin removal tool, plastic tank scraper, construction platform tool, cutters, squeeze bottle and disposable nitrile gloves.

Packaging:

- 1 set

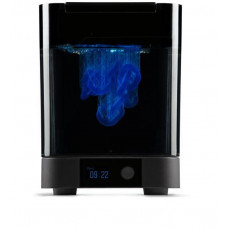

Formlabs Form Wash (2nd Generation)

Form Wash automatically cleans printed items thoroughly and effectively using IPA (isopropyl alcohol) or alternative solvents.

- Prints can be transferred directly on the build platform from the printer to Form Wash or removed and placed in the washing basket.

- Prints are precisely and thoroughly mixed in the solvent using a rotor, thanks to which every corner and crevice is perfectly clean.

- Once washing is complete, Form Wash automatically lifts the models from the IPA to dry.

Packaging:

- 1 piece

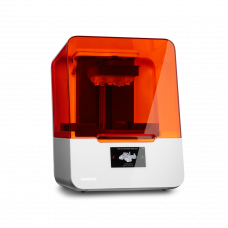

Formlabs Form 4B 3D printer

The Form 4B 3D printer is another proposition from Formlabs. Never before has the dental and medical industry had access to such a combination of quality, speed and user experience in the desktop printer segment.

Formlabs Form 4B with new LFD™ technology

The Form 4B printer works with the newly patented Low Force Display™ technology. It operates on the basis of six advanced print control systems, a new resin container with a dosing system and a larger printing platform than in previous models. The dimensions of the new work platform are 200 × 125 × 210 mm, which is 30% more than before.

Printing speeds of up to 100 mm/h deliver ready models in less than 2 hours. A 50 micron pixel is used for maximum dimensional accuracy.

The Form 4 3D printer is a solution designed for the dental and medical industries. Form 4B supports all materials available for Form 4 engineering printing, plus dental, medical materials and biocompatible resins. A wide selection of materials will be used in the everyday work of dental technicians, dentists and medical research laboratories. The combination of the speed of new LFD technology, high-quality print surfaces and specialized materials expands the possibilities for digital medicine and dentistry. From medical scan to printout in 2 hours? - from now on it is possible with the new Form 4B printer.

The most important benefits of the new Form 4B series compared to previous models:

- New 3D printing technology – Low Force Display™

- Save time – print parts up to 5 times faster.

- Cheaper operation - lower costs of resin tank with extended service life and reduced cost of basic materials by 27%

- Larger work area - work platform increased by 30% with dimensions of 20×12.5×21cm.

- Greater dimensional accuracy – new optical engine.

Technical Specifications:

- Technology: Low Force Display™ (LFD)

- Working area: 20.0 × 12.5 × 21.0 cm

- Layer thickness: 25 – 300 microns

- XY resolution: 50 microns

- Average printing speed: 40 mm/h

- Maximum printing speed: 100 mm/h

- Resin tank life: 75,000+ layers with any Formlabs material

- Printer weight: 18.3 kg

- Printer dimensions: 39.8 × 36.7 × 55.4 cm

- Warranty and service: 1-year warranty included

- Paid service and extended warranty options: available

Accepted file types: STL, OBJ, 3MF

Packaging:

1x printer

- 1x Resin Tank form 4B

- 1x form 4B work platform

- 1x Mixer form 4B

- 1x Finish kit

The printer is available in 3 warranty options: - 1 year warranty - 2 years warranty - 3 years warranty

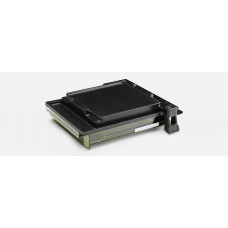

Formlabs Form 4 Mixer

The Form 4 resin mixer improves material efficiency by maintaining the uniformity of the resin in the tank during the printing process. A mixer is required for every printing. For convenience, we recommend having one resin mixer per tank.

Packaging:

- 1 piece

Formlabs Resin Pump

Formlabs resin pump.

The resin pumping system for Form 3 series stereolithography (SLA) 3D printers smoothly delivers resin from a 5 liter resin package through the pumping system directly to the printer tank. Reduce waste by 86%.

Packaging:

- 1 piece

Formlabs Resin Tank for Form 4

Each resin tank includes a reusable lid that makes it easy to stack the tanks and store the resin outside the printer. With a separate tank for each color or type of resin, changing materials is as easy as inserting a new tank.

Resin tanks provide consistent performance for at least 75,000 layers of printing (typically 1-2 years for the average user).

Packaging:

- 1 piece

Formlabs Resin Tank Form 3L

Resin tray.

Original spare part for the Formlabs Form 3L 3D printer.

Packaging:

- 1 piece

Formlabs Form 3 Finish Kit

The Finish Kit accessory package helps keep your workspace clean and tidy, while giving the final touch to your masterpieces.

Includes rinsing station, 2 rinsing buckets, rinsing basket, rinsing bottle, finishing tray, reservoir tool, tweezers, scraper, removal tool, cutters and disposable nitrile gloves.

Packaging:

- 1set

Formlabs Form 3B+ 3D printer

Dental 3D printer for orthodontics, prosthetics and implantology.

Printing technology:

- Low Force Stereolithography™ (LFS).

- Working area 145 × 145 × 185 mm.

- Layer height 25 – 300 microns.

- Laser spot size 85 micrometers.

The Formlabs Form 3B+ 3D printer was created specifically for dental applications. High printing precision was achieved thanks to the use of an improved version of stereolithography (SLA). The laser spot is only 0.085 mm, which gives ultra-precise dimensional accuracy. LFS technology enables fast, efficient and reliable manufacturing with a precision of 25 micrometers. This is confirmed by the reputation of Formlabs devices. The availability of 20 materials for 3D printing, including dental and biocompatible materials, translates into wide use in orthodontics, implantology and prosthetics. An improved optical system, updated 3D printer software and new components make the latest version of the Form 3B+ 3D printer guarantee even greater reliability, precision and speed of 3D printing.

Advantages:

- The Form 3B+ 3D printer is compatible with PreForm software, Formlabs dental resins and post-processing devices: Form Wash and Form Cure.

- Convenience of use, easy and clean operation, thanks to replaceable 1-liter material cartridges. Upload designs for printing via Wi-Fi, USB or Ethernet.

- Technical support, you can count on our help at the stage of choosing a 3D printer, as well as after the purchase. We provide professional training, technical support and post-warranty care.

Technical data:

- Working area: 145 x 145 x 185 mm

- Materials: Standard, Castable Wax, Denture Base and Teeth, Dental Model, Dental SG, Dental LT Clear

- Laser spot diameter: 85 micrometers

- Laser power: 250 kW

- Software: Preform

- Layer height: 25-300 micrometers

- Dimensions: 405 x 375 x 530 mm

- Weight: 17.5 kg

Packaging:

- 1 piece

Formlabs Form Wash - a device for cleaning models after printing

Form Wash, a washer for cleaning models from resin residues.

- Automatic washer for cleaning models from uncured resin residues using SLA technology.

- Post-processing device compatible with Formlabs Form 2 3D printers.

- The rotor circulates isopropyl alcohol (IPA), which ensures effective and efficient rinsing of unnecessary material in every detail.

- The washer is equipped with a special handle, thanks to which we can move the work platform with prints and mount it directly in the washer or remove the model from the work table and place it in the basket.

Advantages:

- Automatic cleaning - the device will remove the model from the bath after finishing work.

- 15 minutes - average cleaning time for fresh isopropyl alcohol.

- 8.6 l - tank volume.

- 70 prints - the number of cleaned prints for one tank refill.

- The device's mechanism will automatically remove the models from the IPA after a certain period of time, which is set on a timer. This limits the risk of damaging the print due to too long soaking in IPA. The models are dry and ready without user participation in the post-processing process.

Packaging:

- 1 piece.

Formlabs Form Cure light polymerization device

Form Cure light polymerization lamp.

Advantages:

- 80 °C - an advanced heating system precisely controls the curing temperature.

- 405 nanometers - optimal wavelength of light for hardening models made of Formlabs materials.

- 13 multi-directional LEDs emit constant light.

- 1 revolution per minute - the rotary table ensures uniform exposure of each model.

Exposure improves the properties of photopolymer resin prints:

- Standard resins achieve better mechanical strength

- Engineering resins require irradiation to achieve their declared mechanical values

- Casting resins allow for cleaner firing

- Curing biocompatible resins is essential for applications in medicine and dentistry

- The heating system heats the chamber to ensure optimal curing conditions.

Packaging:

- 1 piece.

Formlabs Resin Tank FORM 2 - resin container

Resin container compatible with the Formlabs Form 2 printer.

Enough for about 20 resin fillings.

Packaging:

- 1 piece.

Formlabs Resin Tank LT - extended-life resin container for the Form 2 printer

Extended-life resin container recommended for use with the Formlabs Form 2 printer.

Packaging:

- 1 piece.

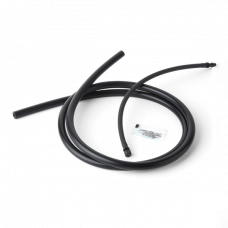

Formlabs Maintenance Kit

Spare hoses for the resin pumping system. Over time, pump performance will deteriorate, resulting in longer filling times. The resin pumping system tubing should be replaced every 6 months or when the resin type changes. This kit includes both an internal tube for the resin pump and a transfer tube to connect the resin pump to the 5 liter resin container.

Packaging:

- 1 set of hoses

Formlabs Resin Tank for FORM3 version 2.1

Formlabs Resin Tank FORM 3 - resin tank.

Formlabs Resin Tank for FORM3 version 2.1

Packaging:

- 1 piece

Formlabs Build Platform 2 for Form 3 Printers

Flexible Formlabs Build Platform 2.

- The new work platform has a flexible surface and comfortable handles. In one simple movement, printed parts are instantly removed from this coating without the use of tools. The platform eliminates the risk of part damage and optimizes workflow.

Packaging:

- 1 piece

Formlabs Work platform for Form 2 and Form 3 printers

A spare build plate can speed up your workflow and allow for uninterrupted printing.

Packaging:

- 1 piece