CNC milling machines in dental technology The design stage usually ends with the final prosthetic work. Currently, various types of milling devices are used. Depending on the needs of the user, the machine is qualified in terms of:

- the number of working axles - usually 3 or 5,

- type of processed material,

- spindle power and machine weight.

The number of axes used affects the quality of the machined surface and the cut solid. In technical terminology, the X axis is distinguished - moving the working field to the right and left, the Y axis - moving forward and backward, the Z axis - lifting to the height and the AB axis, i.e. turning the working area by 180 degrees. In the case of 5-axis machines, we also deal with the angular deviation of the working field, which increases the possibility of cutting in undercuts. Of course, not all prosthetic works require full 5-axis machining. A simple element without angular diversion, e.g. an implant abutment hole, can be easily cut in a 3-axis machine.

In the case of complex implantological works with different directions of insertion of fastening screws, more and more popular full-contour crowns require processing in 5 axes. Therefore, the choice of the machine is dictated by the scope of work to be performed. As mentioned, an important parameter is the type of material that will be milled in our machine. In this case, two subgroups can be distinguished:

- milling of soft materials, such as pre-sinterized zirconium oxide or CoCr alloy, leucite ceramics, wax, PMMA or new generation materials called hybrid,

- milling of metal alloys: CoCr and titanium.

The first group does not require machines with a rigid and heavy structure. The rotary range of the spindles used is 150–800 watts. Usually these are cutting machines without water cover. Users who want to machine materials from the group of leucite ceramics or partially sintered ceramics (EMAX) will need machines that operate in a full water jacket. Ceramics is a material with amazing thermal insulation parameters, but too much heat accumulation generated during the friction of a diamond tool may cause local overheating and flaking of the material. The coolants used are usually a mixture of water and organic fluids that give the cutting tool a slight glide, do not discolor and do not chemically adhere to the material being processed.

Hard metal milling requires rigid machines weighing more than 500 kg. The larger and heavier the machine, the easier it is to overcome the resistance of milling. It is important, especially when performing works with an accuracy of 2 μm (implant connectors). Any deviation during machining due to vibrations in the structure causes dimensional distortion. In the most technologically advanced machines, it is required to place the machine on a specially prepared surface with the ideal operating temperature of 21 ± 2 ° C. It should be remembered that the friction generates a high temperature, partially reduced by coolant or compressed air, which should not be increased by the ambient temperature. In precision machine tools, attention is drawn to the possibility of thermal expansion of both the spindle and the cutting tools themselves. Therefore, professional refrigerator solutions work similarly to home refrigerators.

Cerec MC Care Liquid 250ml

MC Care Liquid is a preventive care and cleaning concentrate for use in the wet cleaning procedure of all Dentsply Sirona grinders and milling machines. In addition to its cleaning function, the liquid also has a maintenance function. It gives a pearl effect and has a slight descaling effect. If MC Care Liquid is used in every wet cleaning process, contamination of the processing chamber, hose system and nozzles is significantly reduced.

Packaging:

- 1 piece

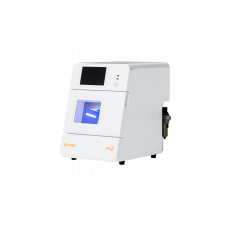

Up3d P42 ceramic milling machine - NEW!!!

P42 milling machine High standards High quality.

COMMERCIAL INFORMATION/CONTACT:

Mikran.pl ul. Wojskowa 3/L4 60-792 Poznań sklep@mikran.pl, www.mikran.pl Possibility of free presentation of the milling machine in your workshop/office.

Call us: +48 600 128 010 or +48 530 596 166.

Advantages:

- Grinding with pure water, you don't need another grinding fluid, take care of the material, say goodbye to cumbersome waste disposal.

- Possibility of grinding many materials (glass ceramics, hybrid, composite, titanium).

- Milling an ultra-thin 0.2 mm veneer.

- P 42 capable of milling to remove undercuts by tilting the A axis by #20° to ensure each restoration is perfectly fitted.

- Simple and easy to use, connected to the UPLink platform for remote monitoring, intelligent and highly efficient.

- CAM software UPCAM (optional Millbox).

Application:

- Veneers.

- Iinlay, onlay.

- Crowns.

- Telescopic crowns.

- Bridges.

- Connectors.

Technical data:

- Weight 80 kg.

- Dimensions 571x449x585 (mm).

- Tool magazine 6 pieces.

- Spindle power 550 W.

- Number of controlled axes 4.

- Stepper motor axis drive.

- Wet working Yes.

- Spindle speed 60,0000 rpm.

- Handle diameter 4 mm.

- CAD/CAM material storage Manual.

- The LED bar displays the machine status.

- Built-in camera to monitor the grinding status.

Packaging:

- 1 piece.

HinriMill E4 milling machine

Digitize your practice with HinriMill e4! You and your patients will benefit from dental restorations in one treatment session. The new HinriMill e4 makes it easy to start fabricating prosthetic restorations at the chairside, giving you maximum freedom. Connect HinriMill e4 to your preferred intraoral scanner, any CAD software and materials appropriate to your patient's case. HinriMill e4 is the heart of your work and performs the perfect restoration for you. With the included CAM software you can get started right away!

Due to its low weight of only 28 kg and the complete absence of compressed air, the HinriMill e4 offers maximum flexibility in positioning. Place HinriMill e4 anywhere. As the motto goes: unpack, turn on, start milling!

Discover AITROOL, a breakthrough technology that gives you incredible freedom and flexibility when processing details. Thanks to Airtoll, our machines no longer require an external compressed air connection or a built-in compressor. Instead, the AIRTOOL turbine blades produce a powerful air flow that protects the workpiece from chips and dust during the milling process. This not only provides a better working environment, but also increases machining efficiency. Join the progress.

Fast and precise:

- Spindle 800 W 60,000 rpm.

- Repetition accuracy 3 μm.

- No compressed air required thanks to the patent-pending AIRTOOL.

- Solid welded aluminum construction.

- 100% developed and manufactured in Germany.

- DENTALCAM software with an open interface to CAD software and materials.

- Any intraoral scanners can be used.

- Mills almost all blocks up to 45 mm long from many manufacturers (glass ceramics, composites, zirconium and plastics)

Advantages:

- Four-axis milling machine.

- 7 tools.

- 1 block.

- Wet and dry milling.

Packaging:

- 1 piece

P53DC Up3D zirconia milling machine - test it for free - call our representative!

The latest milling machine from UP3D P53DC equipped with a disk changer is a real "game changer" for your workshop!

A fully automatic milling device, thanks to a large stock of disks and drills, can work for many hours unattended, increasing the productivity of your workshop and saving you time and money!

Distinctive device features:

- Automatic calibration: the most convenient "smart control" system stands out from the competition.

- Vertical Milling 90°: allows easy milling of incisal cavities in front teeth, improving aesthetics.

- C-clamp disk holder: allows for more economical material consumption and 100% disk utilization.

- Remote control:** enables milling 24 hours a day.

As part of the purchase, the manufacturer UP3D and mikran.pl guarantee:

- Professional technical support and service 24/7.

- 100% commitment and effective resolution of every request.

- No license fees for using the UPCAM device and software after the warranty ends.

- Warranty and post-warranty service.

Technical data:

- Dimensions: 720 x 875 x 630mm

- Weight: 130kg

- Air consumption: Cooling pressure: >0.5Mpa consumption: 40L/min

- Number of axles: 5 axles

- Disk storage: 12 disks

- Tool magazine: 11 tools

- Power: 220V/1.2KW

- Optimal operating temperature: +15℃~+40℃ (we recommend warming up the machine for 1 hour before operation if the room temperature dropped below 0℃)

- Vacuum: 1200m3/h, 1.5KW

- Key parameters: Spindle power 750W, max speed: 60,000 rpm

- Milling range: A: -35~30 B: ±360° Z: -47~50

- Material type: round disks 98.5x max30 mm (block optional)

- Compatible CAM systems: UPCAM,Millbox

- Connection method: network cable

- Mills materials: zirconium, wax, PMMA, composite material, peek co-cr (soft metal)

COMMERCIAL INFORMATION/CONTACT:

- Mikran.pl ul. Wojskowa 3/L4 60-792 Poznań sklep@mikran.pl, www.mikran.pl Possibility of free presentation of the milling machine in your workshop/office. Call us: +48 600 128 010 or +48 530 596 166

Packaging:

- 1 piece

P53 Up3D zirconia milling machine - test it for free - call our representative!

Make an appointment for a free presentation in your studio/office:

Dental tech. Damian Dunajewski Consultant/CAD/CAM Specialist Tel.600 128 010 damian.dunajewski@mikran.com

Dental tech. Kamil Wolniewicz Consultant/CAD/CAM Specialist Tel.530 596 166 kamil.wolniewicz@mikran.com

P53, is a new intelligent UP3D dental milling machine, can mill 44 crowns at a time. A fully intelligent machine will help you save 35% of materials.

Functionalities:

- Fully integrated UP3D UPCAM control software, with a lifetime free license and updates, ensures reliable and safe operation of the device and full control over the quality of work performed - the system of automatic continuation of work from the moment it is interrupted at any time allows you to increase efficiency by up to 80%.

- Automatic integrated lift start.

- Tool life sensor.

- 98.5 type disc holder (open system) - standardly built into the machine.

- The half-moon disc holder allows for maximum use of the material and supports milling at an angle of 90 degrees.

- Automatic calibration.

Application:

- Crowns.

- Bridges.

- Foundations.

- Work on implants.

- Complete dentures.

The device mills soft materials:

- Zirconium.

- Wax.

- PEEK.

- PMMA.

- Gypsum.

Product specification:

- Weight 79 kg

- Dimensions 443.5 × 718 × 628.5 cm

- Power 800 W

- Spindle power 520W

- Number of controlled axes 5

- Tool magazine 11 pieces

- Material PEEK, PMMA, Sintermetal, Zirconium oxide (Zr), Wax

- Wet working No

- Spindle speed 60,0000 rpm

- CAD/CAM material storage Manual

- Stepper motor axis drive

- Handle diameter 4 mm

COMMERCIAL INFORMATION/CONTACT:

- Possibility of free presentation of the milling machine in your workshop/office. Call us: +48 600 128 010or +48 530 596 166

Packaging:

- 1 piece