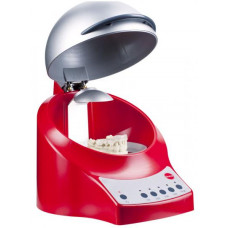

LED lamp for polymerization of MAXI spoons

LED lamp for hardening materials for individual trays and other light-curing materials.

Characteristics:

- Optimal lighting of the polymerization chamber: 4 LED fluorescent lamps emitting in the range of 365-405 nm.

- Fast hardening thanks to the special arrangement of efficient fluorescent lamps and reflectors.

- Uniform cure in 0-15 minutes with set exposure time and automatic shut-off function controlled by a mechanical timer.

- Large polymerization chamber that can accommodate up to 4 models at the same time.

- Simple operation.

- High level of safety thanks to well-insulated electronics that meet appropriate standards.

- Low space requirement thanks to compact design.

Technical data:

- External dimensions 215 (L) x 295 (W) x 115 (H) mm.

- Weight 2 kg.

- Voltage 220/240V 50Hz.

- Emission range 365~405 nm.

- Power consumption 9W.

Packaging:

- 1 piece

Dreve EyeVolution curing lamp

EyeVolution curing lamp.

Application:

- Polymerization of individual trays made of light-curing materials.

- Polymerization of light-cured varnishes.

- Polymerization of blocking resins.

- And some composite materials.

Technical data:

- Light length 385 - 390 + 465- 470 nm

- Dimensions 205 x 205 x 255 mm

- Weight 1.5 kg

- Input voltage 100-240V/50-60Hz, 0.7A

- Output voltage 12V, 1.5A

- Maximum power consumption 18W

- RPM plate 4.5 rmp

- Program time 1/2/3/5/10 min

- Warranty 24 months

Packaging:

- 1 piece

SIRIO composite polymerization lamp (halogen + UV)

The SIBARI lamp allows the photopolymerization of all light-curable materials available on the market, including:

- Individual spoons.

- Technical composites.

- Denture varnishes.

- Blockers.

- Composites for the superstructure of thermoformable rails.

The material is placed on a transparent base that rotates, exposing it to light waves. The machine is equipped with a fan that stabilizes the temperature inside the device - this allows safe operation without the risk of overheating the composite.

The maximum temperature inside is 55 °C.

Equipment:

- 8 fluorescent bulbs emitting UVA light and white light.

- Halogen bulb 150W.

- The length of the light wave emitted by the lamp covers the range (320 - 550 nm).

It is possible to turn off the halogen lamp emitting white light.

Parameters:

- Voltage 230V

- Power 320W

- Weight 10kg

Packaging:

- 1 piece.

Power Light curing lamp

Technical data:

- bulbs type UVA + white light + halogen

- emits a temperature of 40 degrees C.

- wavelength 320- 550 nm

It polymerizes most of the composites available on the market, equipped with a rotating table and a temperature stabilization system in the polymerization chamber.

Package:

1 piece.

Lamp for polymerization of OMEC composites

Thanks to the use of modern LED technology, it is perfectly suited for the polymerization of most composites available on the market. The device has a rotating table inside the chamber.

The device uses 3 different types of light sources, two types of LED diodes and one halogen bulb which additionally emits a temperature of 45 ° C. The temperature inside the device is stabilized by a fan. It has a rotating table with a mirror surface that makes it easier for light waves to reach even the largest arcades.

Technical data:

- Voltage: 230V / 50 Hz

- Power: 150 W

- Table dimensions: 15x16x10h cm

- Weight: 8 Kg

- Dimensions: 30x35x35h cm

Package:

1 piece.

Dreve Lamp Eye Volution MAX

A new lamp for the polymerization of light-cured composites. Thanks to the DWL (double wavelength light) technology, it perfectly copes with both small works and large bridges on a metal foundation.

ATTENTION:

The lamp will cure 100% of any technical composite!

Wavelength 385-465nm + 465-47nm, and a reverse table (180 degree rotation technology) make this compact device unmatched among other lamps for composite polymerization available on the market. The use of LED technology allows for many years of trouble-free use of the lamp, even in an intensive cycle.

Dimensions: 205 x 205 x 255 mm Weight: 1.8 kg Socket: 100-240 V / 50-60 Hz, 0.7 A Power consumption: max. 30 W Wavelength: 385-390 + 465-470 nm Programs (cycles): 1/2/3/5/10 min

Package:

1 piece

Mestra SUN BEAM 3D UV lamp

Thanks to its size and efficiency, the lamp is capable of hardening materials used in the dental industry, including models printed on 3D printers.

Professional polymerization quality.

The device emits constant, concentrated and uniform 360° UV light to quickly harden photopolymer resins. The secondary hardening process increases the hardness and strength of printed products.

Compact, simple and elegant design, with an 18 cm diameter turntable that guarantees even hardening for a large volume of work.

The Sun Beam 3D has a door design that provides very convenient access for inserting or removing models.

Control panel:

- Display showing power level, curing time or turntable setting.

- While hardening, a timer appears on the display.

Technical data:

Chamber dimensions: Ø180 x 200 mm.

External dimensions: 225 x 225x x 352 mm.

Wavelength: 375 ~ 405nm.

Weight: 3 kg.

Curing time: 1 - 60 minutes.

Rotation speed: 60 seconds/lap.

Advantages:

- SUN BEAM 3D is equipped with UV LEDs.

- The light source does not produce ozone, it is environmentally friendly.

- The lamp consumes little electricity.

- The lamp life can last up to 10,000 hours, which is a long-term safe purchase for the laboratory.

Packaging:

- 1 piece

IP Lighting Pro Curing lamp

The new versatile IP Lighting Pro light curing lamp with modern LED technology.

The latest generation of light curing with advanced LED technology for optimal curing.

- Veneering composites.

- 3D printing materials.

- Individual spoon materials.

Advantages:

- Very broad wave spectrum 380 - 650 nm.

- Efficiency and exposure depth.

- Reduces curing time by up to 50% compared to conventional halogen curing lamps.

- LED chips guarantee a much longer life compared to halogen, xenon or fluorescent lamps.

- Stainless steel mirror chamber with 160mm diameter transparent turntable and intelligent cooling system.

- Large polymerization chamber.

- Adjustable curing time in minutes and seconds, making it universally adjustable.

Curing time:

- Spoon materials (40-90s).

- Composites (2-3 mins).

- 3D printing materials (3-5 minutes).

Technical data:

- Emission spectrum 380-650 nm.

- LEDs 48x LEDs.

- 115W power

- Voltage 230/110V; 50Hz.

- Dimensions L x W x H 200 x 400 x 340 mm

- Weight 10 kg.

Packaging:

- 1 piece