Diasynt Plus stone DYP-8m

Diasynth Plus medium.

- Synthetically sintered, diamond-impregnated stones for processing zirconia and porcelain (universal).

Advantages:

- Highly abrasive.

- Low heat emission.

- Without the use of a water jacket.

- Perfect for reduction in the margin area.

- Medium gathering pink.

- Recommended operation between 8,000-12,000 rpm, maximum 25,000 rpm

- Diameter 12x2mm.

Packaging:

- 1 piece

Diasynt Plus stone DYP-13m

Diasynth Plus medium.

- Synthetically sintered, diamond-impregnated stones for processing zirconia and porcelain (universal).

Advantages:

- Highly abrasive.

- Low heat emission.

- Without the use of a water jacket.

- Perfect for reduction in the margin area.

- Medium gathering pink.

- Recommended operation between 8,000-12,000 rpm, maximum 25,000 rpm

- Diameter 4x10mm.

Packaging:

- 1 piece

Diapro eraser for lithium disilicate LiSi L26DP

Diapro diamond-coated erasers for finishing and polishing Lithium disilicate works.

Advice:

- For initial grinding we recommend DIASYNT PLUS stones and for initial polishing of Diapro Medium (brown) rubber bands

Characteristics:

- Lime color (fine) final polishing and glossing.

- Speed 7,000- 12,000 rpm max 20,000 rpm

- Size 26x2mm

Packaging:

- 1 piece

Silicone eraser for porcelain and metal, 1 piece

Renfert silicone erasers are recommended for pre-processing of porcelain and metal. Highly abrasive, they do not leave streaks or "orange film" on the treated surface.

Renfert catalog number 860000

Advantages:

- They grind hard - grinding the surface, shaping.

- No streaks on the ceramic surface.

- They are perfect for processing places where the alloy is adjacent to porcelain.

Technical data:

- Ø 22mm.

- Thickness 3.2 mm.

- Maximum speed 15000 rpm

Packaging:

- 1 piece.

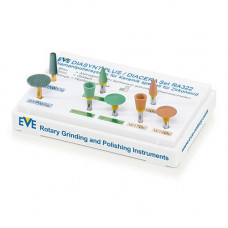

Diasynt Plus / Diapro lithium disilicate polishing set

EVE Diasynt Plus / Diapro

A three-stage set of rubbers and stones for the processing of lithium disilicate

Kit composition:

- DIASYNT PLUS stones - pretreatment,

- DIAPRO brown rubbers - smoothing and pre-polishing,

- DIAPRO lime rubbers - high gloss polishing.

Recommended for polishing restorations made of IPS e.max press and other restorations made of Lithium Disilicate, e.g. AMBER Mill

Package:

- stones - 3 pcs

- medium brown erasers - 3 pcs

- fine lime rubber bands - 3 pcs

CeraMaster HP WH6 erasers, pack of 3

Silicone erasers filled with natural diamond particles for quick finishing and polishing of ceramic restorations.

Advantages:

- They do not require polishing paste.

- Long lasting service life.

- Low heat generation.

Packaging:

- 3 pieces

Dynex Brillant discs for lithium disilicate 20x0.8mm 1 pc

Glass fiber reinforced diamond grinding discs, designed for processing and cutting ceramic materials, especially suitable for lithium disilicate.

Renfert catalog number 560820

Advantages:

- They prevent cracking of ceramic materials due to low heat generation.

- Safe trimming of filler channels thanks to very high removal efficiency.

- Gentle to the material thanks to extremely low vibrations

- Max speed 50000 rpm

Packaging:

- 1 piece

Silicone eraser for porcelain and metal, 100 pieces

Renfert silicone erasers are recommended for pre-processing of porcelain and metal. Highly abrasive, they do not leave streaks or "orange film" on the treated surface.

Renfert catalog number 860000

Advantages:

- They grind hard - grinding the surface, shaping.

- No streaks on the ceramic surface.

- They are perfect for processing places where the alloy is adjacent to porcelain.

Technical data:

- Ø 22mm.

- Thickness 3.2 mm.

- Maximum speed 15000 rpm

Packaging:

- 100 pcs.

Zirconium development kit for the dentist

A set of rubber bands and stones for the contra-angle for the preparation of zirconium by the dentist.

Package:

1 set

Diapro Twist eraser for Lithium Disilicate LiSi DT-H17DPmf

Diaphragm rubbers with diamond coating for processing and polishing works made of Lithium Disilicate.

Advice:

- we recommend DIASYNT PLUS stones for initial grinding

Characteristics:

- Brown color (medium). Pre-polishing.

- Speed 7.000- 12.000 rpm, max.20.000 rpm

- Size 17x1.8mm

Package:

- 1 piece

Set of instruments for the development of zirconium

Instrument Kit for zirconium processing.

Package:

1 set includes 8 pieces of instruments:

- 1 diamond separator with a diameter of 0.17mm

- 2 rough processing stones

- 2 pre-polishing erasers.

- 1 final polisher

- 2 diamond drill bits per turbine.

Dynex Brillant for ceramics 20x0.25mm 1 piece

Extremely durable separators with double cross-reinforcement and diamond filling.

Renfert catalog number 562520

Application:

- They are perfect for processing porcelain, zirconium and lithium disilicate (IPS e.max press).

Advantages:

- Extra-thin for precise separation of interdental spaces.

- The high elasticity factor facilitates the development of rounded spaces at the enamel and at the step.

- They do not vibrate.

- They do not heat up, so they do not damage the ceramics (important for pressed ceramics).

Characteristic:

- Maximum speed 50,000 rpm (it is recommended to use speeds up to 15,000 rpm)

- Diameter 20 mm

- Thickness 0.25 mm

Packaging:

- 1 piece

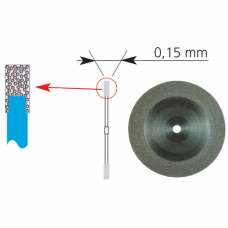

DFS Sidia Flex diamond separator

The dial is covered with sintered diamond on both sides.

Characteristics:

- For the separation of porcelain and zirconium oxide.

- Extremely durable.

- Operating range 3000 - 5000 rpm.

- Disc diameter 20 mm.

- Thickness 0.15mm.

Packaging:

- 1 piece

Stone Diasynt Plus DYP-8g

Diasynt Plus coarse

Synthetically sintered diamond-impregnated stones for processing zircon and porcelain (universal)

Advantages:

- highly abrasive

- low heat emission

- without the use of a water jacket

- perfect for reduction in the margin area.

- green strongly picking,

- recommended operation between 8.000-12.000 rpm, maximum 25.000 rpm

- diameter 12x2mm

Package:

1 piece

Stone Diasynt Plus DYP-13g

Diasynt Plus coarse Synthetically sintered, diamond-impregnated stones for the treatment of zircon and porcelain (universal).

Advantages:

- highly abrasive

- low heat emission

- without the use of a water jacket

- perfect for reduction in the margin area.

- green strongly picking,

- recommended operation between 8.000-12.000 rpm, maximum 25.000 rpm

- diameter 11.5x3mm

Package:

1 piece

Diapro eraser for Lithium Disilicate LiSi H2DP

Diaphragm rubbers with diamond coating for processing and polishing works made of Lithium Disilicate.

Advice:

- for preliminary grinding we recommend DIASYNT PLUS stones and for preliminary polishing of Diapro Medium rubbers (brown)

Features:

- Lime color (fine) final polishing and glossy finish.

- Speed 7.000- 12.000 rpm, max.20.000 rpm

- Size 4x13mm

Package:

1 piece.

Diapro eraser for Lithium Disilicate LiSi L26DPmf

Diaphragm rubbers with diamond coating for processing and polishing works made of Lithium Disilicate.

Advice:

- we recommend DIASYNT PLUS stones for initial grinding

Features:

- Brown color (medium) pre-polishing.

- Speed 7.000- 12.000 rpm, max.20.000 rpm

- Size 26x2mm

Package:

1 piece

Zirconium Oxide Development Kit HP321

EVE Diasynt Plus / Diacera set

Three-step system for developing Zirconium Oxide:

- DIASYNT PLUS stones, preliminary grinding.

- DIACERA medium erasers (green) - smoothing and pre-polishing.

- DIACERA fine erasers, beige color - high gloss polishing.

Packaging:

- Stones - 3 pcs

- Medium rubber bands, green - 3 pcs

- Fine, beige rubber bands - 3 pcs

Diacera Zirconium Oxide L26DCmf

Diacera diamond coated erasers for polishing and polishing works made of Zirconium Oxide.

Advice:

- We recommend DIASYNT PLUS stones for initial grinding

Characteristics:

- Green (medium) pre-polishing.

- Speed 7.000- 12.000 rpm, max.20.000 rpm

- Size 26x2mm

Package:

-1 piece

Diacera L26DC Zirconium Oxide Eraser

Diacera diamond coated erasers for polishing and polishing works made of Zirconium Oxide.

Advice:

- For preliminary grinding, we recommend DIASYNT PLUS stones, for preliminary polishing of the DIACERA medium (green)

Characteristics:

- Beige (fine) color high gloss polishing.

- Speed 7.000- 12.000 rpm, max.20.000 rpm

- Size 26x2mm

Package:

- 1 piece

Diapro Twist eraser for Lithium Disilicate LiSi DT-H17DP

Diaphragm rubbers with diamond coating for processing and polishing works made of Lithium Disilicate.

Advice:

- We recommend DIASYNT PLUS stones for preliminary grinding and Diapro Medium (brown) for preliminary polishing of rubber bands.

Characteristics:

- Lime color (fine) final polishing and glossy finish.

- Speed 7.000- 12.000 rpm, max.20.000 rpm

- Size 17x1.6mm

Package:

- 1 piece

Diapro eraser for Lithium Disilicate LiSi SL20DPmf

Diaphragm rubbers with diamond coating for processing and polishing works made of Lithium Disilicate.

Advice:

- we recommend DIASYNT PLUS stones for initial grinding

Features:

- Brown color (medium) pre-polishing.

- Speed 7.000- 12.000 rpm, max.20.000 rpm

- Size 20x1mm

Package:

1 piece

Diapro eraser for Lithium Disilicate LiSi H2DPmf

Diaphragm rubbers with diamond coating for processing and polishing works made of Lithium Disilicate.

Advice:

- we recommend DIASYNT PLUS stones for initial grinding

Features:

- Brown color (medium) pre-polishing.

- Speed 7.000- 12.000 rpm, max.20.000 rpm

- Size 4x13mm

Package:

1 piece

Diapro eraser for Lithium Disilicate LiSi H8DPmf

Diaphragm rubbers with diamond coating for processing and polishing works made of Lithium Disilicate.

Advice:

- we recommend DIASYNT PLUS stones for initial grinding

Features:

- Brown color (medium) pre-polishing.

- Speed 7.000- 12.000 rpm, max.20.000 rpm

- Size 11x2mm

Package:

1 piece

Diapro eraser for Lithium Disilicate LiSi SL20DP

Diaphragm rubbers with diamond coating for processing and polishing works made of Lithium Disilicate.

Advice:

- for preliminary grinding we recommend DIASYNT PLUS stones and for preliminary polishing of Diapro Medium rubbers (brown)

Features:

- Lime color (fine) final polishing and glossy finish.

- Speed 7.000- 12.000 rpm, max.20.000 rpm

- Size 20x1mm

Package:

1 piece

Diapro eraser for Lithium LiSi H8DP

Diaphragm rubbers with diamond coating for processing and polishing works made of Lithium Disilicate.

Advice:

- for preliminary grinding we recommend DIASYNT PLUS stones and for preliminary polishing of Diapro Medium rubbers (brown)

Features:

- Lime color (fine) final polishing and glossy finish.

- Speed 7.000- 12.000 rpm, max.20.000 rpm

- Size 11x2mm

Package:

1 piece

Diacera Zirconium Oxide Rubber SL20DCmf

Diacera diamond coated erasers for processing and polishing works made of Zirconium Oxide.

Advice:

- we recommend DIASYNT PLUS stones for initial grinding

Features:

- Green color (medium) pre-polishing.

- Speed 7.000- 12.000 rpm, max.20.000 rpm

- Size 20x1mm

Package:

1 piece

Diacera of the Zirconium Oxide H2DC eraser

Diacera diamond coated erasers for processing and polishing works made of Zirconium Oxide.

Advice:

- for preliminary grinding we recommend DIASYNT PLUS stones, for preliminary polishing of the rubber DIACERA medium (green)

Features:

- Color beige (fine) high gloss polishing.

- Speed 7.000- 12.000 rpm, max.20.000 rpm

- Size 26x2mm

Package:

1 piece

Diacera eraser for H8DC Zirconium Oxide

Diacera diamond coated erasers for processing and polishing works made of Zirconium Oxide.

Advice:

- for preliminary grinding we recommend DIASYNT PLUS stones, for preliminary polishing of the rubber DIACERA medium (green)

Features:

- Color beige (fine) high gloss polishing.

- Speed 7.000- 12.000 rpm, max.20.000 rpm

- Size 26x2mm

Package:

1 piece

Diacera Zirconium Oxide H2DCmf

Diacera diamond coated erasers for processing and polishing works made of Zirconium Oxide.

Advice:

- we recommend DIASYNT PLUS stones for initial grinding

Features:

- Green color (medium) pre-polishing.

- Speed 7.000- 12.000 rpm, max.20.000 rpm

- Size 4x13mm

Package:

1 piece

Diacera Zirconium Oxide eraser H8DCmf

Diacera diamond-filled eraser for processing and polishing works made of Zirconium Oxide.

Advice:

- We recommend DIASYNT PLUS stones for initial grinding

Characteristics:

- Green color (medium), pre-polishing.

- Speed 7,000- 12,000 rpm max 20,000 rpm

- Size 11x2mm

Packaging:

1 piece

Diacera eraser for Zirconium Oxide SL20DC

Diacera diamond coated erasers for processing and polishing works made of Zirconium Oxide.

Advice:

- for preliminary grinding we recommend DIASYNT PLUS stones, for preliminary polishing of the rubber DIACERA medium (green)

Features:

- Color beige (fine) high gloss polishing.

- Speed 7.000- 12.000 rpm, max.20.000 rpm

- Size 26x2mm

Package:

1 piece

Stone Diasynt Plus DYP-14g

Diasynt Plus coarse

Synthetically sintered diamond-impregnated stones for processing zircon and porcelain (universal)

Advantages:

- highly abrasive

- low heat emission

- without the use of a water jacket

- perfect for reduction in the margin area.

- green strongly picking,

- recommended operation between 8.000-12.000 rpm, maximum 25.000 rpm

- diameter 5x13mm

Package:

1 piece

Stone Diasynt Plus EVE 4x10mm medium collecting for the contra-angle

Diasynt Plus medium contra-angle

Synthetically sintered diamond-impregnated stones for processing zircon and porcelain (universal) For the cecum.

Advantages:

- highly abrasive

- low heat emission

- without the use of a water jacket

- perfect for reduction in the margin area.

- pink medium picking,

- recommended operation between 7,000-10,000 rpm, maximum 20,000 rpm

- diameter 4x10mm

Package:

1 piece

Stone Diasynt Plus DYP-14m

Diasynt Plus medium

Synthetically sintered diamond-impregnated stones for processing zircon and porcelain (universal)

Advantages:

- highly abrasive

- low heat emission

- without the use of a water jacket

- perfect for reduction in the margin area.

- pink medium picking,

- recommended operation between 8.000-12.000 rpm, maximum 25.000 rpm

- diameter 5x13mm

Package:

1 piece

Diasynt Plus Stone DYP-22 / 4g

Diasynt Plus coarse

Synthetically sintered diamond-impregnated stones for processing zircon and porcelain (universal)

Advantages:

- highly abrasive

- low heat emission

- without the use of a water jacket

- perfect for reduction in the margin area.

- green strongly picking,

- recommended operation between 8.000-12.000 rpm, maximum 25.000 rpm

- diameter 22x4mm

Package:

1 piece

Stone Diasynt Plus DYP-22 / 2g

Diasynt Plus coarse

Synthetically sintered diamond-impregnated stones for processing zircon and porcelain (universal)

Advantages:

- highly abrasive

- low heat emission

- without the use of a water jacket

- perfect for reduction in the margin area.

- green strongly picking,

- recommended operation between 8.000-12.000 rpm, maximum 25.000 rpm

- diameter 22x2mm

Package:

1 piece

Stone Diasynt Plus DYP-9g

Diasynt Plus coarse

Synthetically sintered, diamond-impregnated stones for processing zircon and porcelain (universal).

Benefits:

- highly abrasive

- low heat emission

- without the use of a water jacket

- perfect for reduction in the margin area.

- green strongly picking,

- recommended operation between 8,000-12,000 rpm, maximum 25,000 rpm

- diameter 11.5x3mm

Package:

1 piece

Stone Diasynt Plus DYP-14Bg

Diasynt Plus coarse

Synthetically sintered diamond-impregnated stones for processing zircon and porcelain (universal)

Advantages:

- highly abrasive

- low heat emission

- without the use of a water jacket

- perfect for reduction in the margin area.

- green strongly picking,

- recommended operation between 8.000-12.000 rpm, maximum 25.000 rpm

- diameter 6.5x13 mm

Package:

1 piece

Diasynt Plus Stone DYP-15g

Diasynt Plus coarse

Synthetically sintered diamond-impregnated stones for processing zircon and porcelain (universal)

Advantages:

- highly abrasive

- low heat emission

- without the use of a water jacket

- perfect for reduction in the margin area.

- green strongly picking,

- recommended operation between 8.000-12.000 rpm, maximum 25.000 rpm

- diameter 15x3mm

Package:

1 piece

Stone Diasynt Plus DYP-22 / 4m

Diasynt Plus medium

Synthetically sintered diamond-impregnated stones for processing zircon and porcelain (universal)

Advantages:

- highly abrasive

- low heat emission

- without the use of a water jacket

- perfect for reduction in the margin area.

- pink medium picking,

- recommended operation between 8.000-12.000 rpm, maximum 25.000 rpm

- diameter 22x4mm

Package:

1 piece

Stone Diasynt Plus DYP-22 / 2m

Diasynt Plus medium

Synthetically sintered diamond-impregnated stones for processing zircon and porcelain (universal)

Advantages:

- highly abrasive

- low heat emission

- without the use of a water jacket

- perfect for reduction in the margin area.

- pink medium picking,

- recommended operation between 8.000-12.000 rpm, maximum 25.000 rpm

- diameter 22x2mm

Package:

1 piece

Stone Diasynt Plus DYP-9m

Diasynt Plus medium

Synthetically sintered diamond-impregnated stones for processing zircon and porcelain (universal)

Advantages:

- highly abrasive

- low heat emission

- without the use of a water jacket

- perfect for reduction in the margin area.

- pink medium picking,

- recommended operation between 8.000-12.000 rpm, maximum 25.000 rpm

- diameter 11.5x3mm

Package:

1 piece

Stone Diasynt Plus DYP-14Bm

Diasynt Plus medium

Synthetically sintered diamond-impregnated stones for processing zircon and porcelain (universal)

Advantages:

- highly abrasive

- low heat emission

- without the use of a water jacket

- perfect for reduction in the margin area.

- pink medium picking,

- recommended operation between 8.000-12.000 rpm, maximum 25.000 rpm

- diameter 6.5x13mm

Package:

1 piece

Stone Diasynt Plus DYP-15m

Diasynt Plus medium

Synthetically sintered diamond-impregnated stones for processing zircon and porcelain (universal)

Advantages:

- highly abrasive

- low heat emission

- without the use of a water jacket

- perfect for reduction in the margin area.

- pink medium picking,

- recommended operation between 8.000-12.000 rpm, maximum 25.000 rpm

- diameter 15x3mm

Package:

1 piece

Stone Diasynt Plus DYP-W11g contra-angle

Diasynt Plus coarse contra-angle

Synthetically sintered diamond-impregnated stones for processing zircon and porcelain (universal) For katnica.

Advantages:

- highly abrasive

- low heat emission

- without the use of a water jacket

- perfect for reduction in the margin area.

- green very picking

- recommended operation between 7,000-10,000 rpm, maximum 20,000 rpm

- diameter 3x7.5mm

Package:

1 piece

Stone Diasynt Plus DYP-W13g contra-angle

Diasynt Plus coarse contra-angle

Synthetically sintered diamond-impregnated stones for processing zircon and porcelain (universal) For katnica.

Advantages:

- highly abrasive

- low heat emission

- without the use of a water jacket

- perfect for reduction in the margin area.

- green strongly picking,

- recommended operation between 7,000-10,000 rpm, maximum 20,000 rpm

- diameter 11.5x3mm

Package:

1 piece

Stone Diasynt Plus DYP-W9g contra-angle

Diastnt Plus coarse contra-angle

Synthetically sintered diamond-impregnated stones for processing zircon and porcelain (universal) For the cecum.

Advantages:

- highly abrasive

- low heat emission

- without the use of a water jacket

- perfect for reduction in the margin area.

- green strongly picking,

- recommended operation between 7,000-10,000 rpm, maximum 20,000 rpm

- diameter 11.5x3mm

Package:

1 piece

Stone Diasynt Plus DYP-W11m contra-angle

Diasynt Plus medium contra-angle

Synthetically sintered diamond-impregnated stones for processing zircon and porcelain (universal) For the cecum.

Advantages:

- highly abrasive

- low heat emission

- without the use of a water jacket

- perfect for reduction in the margin area.

- pink medium picking,

- recommended operation between 7,000-10,000 rpm, maximum 20,000 rpm

- diameter 3x7.5mm

Package:

1 piece

Stone Diasynt Plus DYP-W9m contra-angle

Diasynt Plus medium contra-angle

Synthetically sintered diamond-impregnated stones for processing zircon and porcelain (universal) For the cecum

Advantages:

- highly abrasive

- low heat emission

- without the use of a water jacket

- perfect for reduction in the margin area.

- pink medium picking,

- recommended operation between 7,000-10,000 rpm, maximum 20,000 rpm

- diameter 11.5x3mm

Package:

1 piece