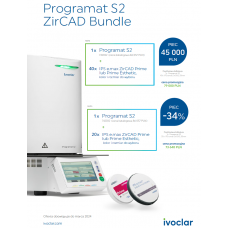

Programat S2 Zirconium sintering furnace PROMOTION

Promotion 1: Programat S2 + 40x IPS e.max ZirCAD Prime or Prime Esthetic (color and size to choose from) - Price PLN 79,000

Promotion 2: Programat S2 + 20 IPS e.max ZirCAD Prime or Prime Estethic (color and size to choose from) - Price PLN 73,640

Programat S2 is a compact oven designed for sintering caps, frameworks and full contour restorations made of IPS e.max ZirCAD or other zirconium oxide materials at temperatures up to 1600°C. Programat S2 is integrated into the Ivoclar workflow, ensuring optimally coordinated processing steps and consistently high-quality results.

Advantages:

Homogeneous heat distribution on objects allows for optimal sintering results at temperatures up to 1600 °C.

With a choice of three heating stages and two cooling stages, the sintering program offers a range of options for zirconium oxide materials.

Optimized cooling shelf provides more space and better cooling.

New, membrane-sealed keyboard with proven color touch display.

OSD display extended with the "cooling down" operating status.

Performance and reliability thanks to software optimization.

Warranty 2 years

Packaging:

- 1 piece.

Aidite sintering beads, diameter 1.0mm (very fine), 500g

High-quality beads for a tray for sintering zirconium works.

- Very fine, diameter 1.0 mm.

Packaging:

- 500 g

Cerec MC Care Liquid 250ml

MC Care Liquid is a preventive care and cleaning concentrate for use in the wet cleaning procedure of all Dentsply Sirona grinders and milling machines. In addition to its cleaning function, the liquid also has a maintenance function. It gives a pearl effect and has a slight descaling effect. If MC Care Liquid is used in every wet cleaning process, contamination of the processing chamber, hose system and nozzles is significantly reduced.

Packaging:

- 1 piece

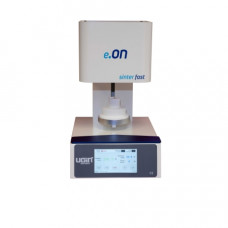

Ugin Litter box with lid for e.on sinter+/ base/fast

Cuvette with lid for zirconium sintering.

Technical data:

- Diameter 10 cm

- Height 3.5 cm

- Lid height 0.5 cm

Packaging:

- 1 piece

MICRO WAVES zirconium sintering furnace

NEW - Microwaves in zirconium oxide sintering.

Main advantages compared to conventional sintering furnaces:

- The total sintering time is approximately 4 hours

- Sintering time up to 1550 ºC: 110 min.

- Cooling to 300 ºC: 130 min.

Unlike conventional sintering units - where heat passes from the outside of the structure to the inside - in a microwave oven, heat is generated at all points in the structure, so the temperature is achieved more evenly. The resulting structure is cleaner, more durable and precise because there are no drafts during heating.

Zirconium is an excellent heat-resistant material. In a traditional oven, heating must be done gradually, observing levels, so that the temperature is evenly distributed throughout the prosthesis. Hence the long duration of sintering programs.

By using a microwave device, you will save on maintenance due to lower power, fewer components and smaller size.

- It does not contain delicate and expensive molybdenum silicate heating elements.

- Very low consumption: approximately 800/1100 W during the entire cycle.

- Possibility to carry out several production cycles on the same day.

- Production capacity increases rapidly.

- Extremely easy to use.

- Much smaller than standard ovens.

- It emits virtually no heat, which is appreciated in closed rooms in the summer.

- The stove is supplied with all necessary accessories for immediate operation

Technical data:

- Dimensions: 385 (W) x 440 (D) x 547 (H) mm.

- Weight: 31 kg.

- Power supply: AC 230 V, 50 Hz.

- Fuse: 15 A.

- Power: 2000 W

- Maximum temperature: 1550ºC.

Packaging:

- 1 piece

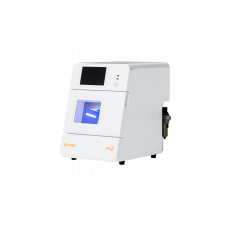

Up3d P42 ceramic milling machine - NEW!!!

P42 milling machine High standards High quality.

COMMERCIAL INFORMATION/CONTACT:

Mikran.pl ul. Wojskowa 3/L4 60-792 Poznań sklep@mikran.pl, www.mikran.pl Possibility of free presentation of the milling machine in your workshop/office.

Call us: +48 600 128 010 or +48 530 596 166.

Advantages:

- Grinding with pure water, you don't need another grinding fluid, take care of the material, say goodbye to cumbersome waste disposal.

- Possibility of grinding many materials (glass ceramics, hybrid, composite, titanium).

- Milling an ultra-thin 0.2 mm veneer.

- P 42 capable of milling to remove undercuts by tilting the A axis by #20° to ensure each restoration is perfectly fitted.

- Simple and easy to use, connected to the UPLink platform for remote monitoring, intelligent and highly efficient.

- CAM software UPCAM (optional Millbox).

Application:

- Veneers.

- Iinlay, onlay.

- Crowns.

- Telescopic crowns.

- Bridges.

- Connectors.

Technical data:

- Weight 80 kg.

- Dimensions 571x449x585 (mm).

- Tool magazine 6 pieces.

- Spindle power 550 W.

- Number of controlled axes 4.

- Stepper motor axis drive.

- Wet working Yes.

- Spindle speed 60,0000 rpm.

- Handle diameter 4 mm.

- CAD/CAM material storage Manual.

- The LED bar displays the machine status.

- Built-in camera to monitor the grinding status.

Packaging:

- 1 piece.

DD phoeniX sintering oven cleaning powder 200g

DDphoeniX is a powder to help clean soiled sintering ovens. Regular use minimizes the problem of discoloration, thus extending the life of the heaters.

- Sintering - cleaning program - as recommended by the furnace manufacturer.

- Thorough cleaning (in case of problems with the color of works) 30--50 gr X 2 cleaning cycles.

- Regular cleaning (every 2 weeks) approx. 30gr x 1 cleaning cycle.

Precautions:

- When using the powder, use protective gloves and a mask to protect the eyes and mouth.

- Do not eat or drink while using the powder.

- Avoid breathing dust.

- Apply to the sinter tray at a distance and at moderate speed to avoid increased dusting.

Storage:

- Keep tightly closed in the original packaging.

- Store in a cool, dry place.

Packaging:

- 1pc/200g

Silent Power CAM TC extractor for milling machines

Efficient and affordable CAM extractor with collector motor, especially suitable for medium and large CAM systems.

Renfert catalog number 29380000

Advantages:

- Consistently full suction power thanks to automatic filter cleaning.

- Reliable production process thanks to innovative engine technology (3x longer service life compared to conventional collector engines).

- High suction efficiency up to 3980 l/min.

- Bi-directional communication between the suction unit and CAM equipment thanks to the PLC interface.

- Bagless fine filtering technology.

- Easy motor replacement in minutes.

- Work in quiet conditions thanks to low noise level max. 54.3 dB(A).

- 36-month warranty.

Technical data:

- Permissible mains voltage - 220–240 V.

- Permissible network frequency - 50/60 Hz.

- Energy consumption - 850 W (230 V).

- Volume flow - (max.) 3980 l/min.

- Max depression - 281 hPa.

- Engine technology - Manifold.

- Filter technology - bagless.

- Filter quality - Class M according to EN 60335-2-69.

- CAM interface - RJ45 socket.

- Mains input fuse - 2 x 15 A(T).

- Number of suction hoses - 1.

- Sound pressure level (LpA) - 54.3dB(A).

- Weight ~22 kg.

- Dimensions (width x height x depth) - 275x535x540mm.

- Ø internal suction ports - 45mm.

- Ø external suction connections - 50mm.

- Dust container capacity ~7 l.

Packaging:

- SILENT powerCAM TC.

- Quick start guide.

- Quick information card.

- 3 waste bags (1 piece placed in the dust container).

- 2 m suction hose with 2 end silencers.

Tabeo-1/M/Zirkon-100 zirconium sintering furnace

The Tabeo zirconium sintering furnace offers high-quality technology at a good price.

The TABEO series model variants are ideal for complementing smaller CAD/CAM systems or for expanding existing sintering furnaces.

Their respective capacities range from one sintering tray Ø= 100mm to three sintering trays Ø= 120mm. Your sintering program can be easily entered and saved in the program controller, which is adapted to the TABEO series. Pre-set service programs support you with simple maintenance and cleaning of heating systems.

TABEO offers the possibility of deciding on the use of heating systems with heating elements made of MoSi2 or SiC. Both systems are designed for conventional, long-term sintering. Heating elements made of molybdenum disilicide (MoSi2) provide a maximum furnace temperature of 1650°C. Thanks to predefined service programs, dirt on heating elements can be regenerated.

Due to their physical properties, heating elements made of silicon carbide (SiC) provide a maximum furnace temperature of 1550°C. SiC heating elements do not require regeneration using the service program.

Advantages:

- Sintering bowl ø 100mm.

- Capacity for a maximum of 20 individual crowns.

- 9 freely adjustable programs simplify operation.

- Regularly performing pre-set service programs can prevent possible discoloration of the restorations and extend the life of the heating elements and the heating chamber.

- Heating elements made of high-purity molybdenum disilicide

Technical Specifications:

- Dimensions (width x height x depth) 400 x 600 x 400 mm.

- Combustion chamber capacity 1 x sintering bowl ø 100 mm

- Maximum temperature 1650 °C.

- Weight 55 kg.

- Power supply 200 - 240 V (deviation ± 10%).

- Frequency 50/60 Hz.

- Maximum power consumption 1.3 kW.

- Energy consumption/cycle approx. 3.8 kWh.

Packaging:

- 1 piece

HinriMill E4 milling machine

Digitize your practice with HinriMill e4! You and your patients will benefit from dental restorations in one treatment session. The new HinriMill e4 makes it easy to start fabricating prosthetic restorations at the chairside, giving you maximum freedom. Connect HinriMill e4 to your preferred intraoral scanner, any CAD software and materials appropriate to your patient's case. HinriMill e4 is the heart of your work and performs the perfect restoration for you. With the included CAM software you can get started right away!

Due to its low weight of only 28 kg and the complete absence of compressed air, the HinriMill e4 offers maximum flexibility in positioning. Place HinriMill e4 anywhere. As the motto goes: unpack, turn on, start milling!

Discover AITROOL, a breakthrough technology that gives you incredible freedom and flexibility when processing details. Thanks to Airtoll, our machines no longer require an external compressed air connection or a built-in compressor. Instead, the AIRTOOL turbine blades produce a powerful air flow that protects the workpiece from chips and dust during the milling process. This not only provides a better working environment, but also increases machining efficiency. Join the progress.

Fast and precise:

- Spindle 800 W 60,000 rpm.

- Repetition accuracy 3 μm.

- No compressed air required thanks to the patent-pending AIRTOOL.

- Solid welded aluminum construction.

- 100% developed and manufactured in Germany.

- DENTALCAM software with an open interface to CAD software and materials.

- Any intraoral scanners can be used.

- Mills almost all blocks up to 45 mm long from many manufacturers (glass ceramics, composites, zirconium and plastics)

Advantages:

- Four-axis milling machine.

- 7 tools.

- 1 block.

- Wet and dry milling.

Packaging:

- 1 piece

Zotion Sintering tray 1 piece

Sintering cuvette in the Zotion F2 furnace.

Technical data:

- Outer diameter 10 cm.

- Inner diameter 8.5 cm.

- Height 3 cm.

Packaging:

- 1 piece

P53DC Up3D zirconia milling machine - test it for free - call our representative!

The latest milling machine from UP3D P53DC equipped with a disk changer is a real "game changer" for your workshop!

A fully automatic milling device, thanks to a large stock of disks and drills, can work for many hours unattended, increasing the productivity of your workshop and saving you time and money!

Distinctive device features:

- Automatic calibration: the most convenient "smart control" system stands out from the competition.

- Vertical Milling 90°: allows easy milling of incisal cavities in front teeth, improving aesthetics.

- C-clamp disk holder: allows for more economical material consumption and 100% disk utilization.

- Remote control:** enables milling 24 hours a day.

As part of the purchase, the manufacturer UP3D and mikran.pl guarantee:

- Professional technical support and service 24/7.

- 100% commitment and effective resolution of every request.

- No license fees for using the UPCAM device and software after the warranty ends.

- Warranty and post-warranty service.

Technical data:

- Dimensions: 720 x 875 x 630mm

- Weight: 130kg

- Air consumption: Cooling pressure: >0.5Mpa consumption: 40L/min

- Number of axles: 5 axles

- Disk storage: 12 disks

- Tool magazine: 11 tools

- Power: 220V/1.2KW

- Optimal operating temperature: +15℃~+40℃ (we recommend warming up the machine for 1 hour before operation if the room temperature dropped below 0℃)

- Vacuum: 1200m3/h, 1.5KW

- Key parameters: Spindle power 750W, max speed: 60,000 rpm

- Milling range: A: -35~30 B: ±360° Z: -47~50

- Material type: round disks 98.5x max30 mm (block optional)

- Compatible CAM systems: UPCAM,Millbox

- Connection method: network cable

- Mills materials: zirconium, wax, PMMA, composite material, peek co-cr (soft metal)

COMMERCIAL INFORMATION/CONTACT:

- Mikran.pl ul. Wojskowa 3/L4 60-792 Poznań sklep@mikran.pl, www.mikran.pl Possibility of free presentation of the milling machine in your workshop/office. Call us: +48 600 128 010 or +48 530 596 166

Packaging:

- 1 piece

Ferro PTCR HTH ring for temperature control of the sintering process, 1 piece

PTCR-HTH 1450 – 1750 °C

Firing temperature control rings are highly accurate ceramic elements that indicate the actual amount of heat that has been absorbed during the firing process. The sintering process causes the ring to shrink. The shrinking process lasts as long as the maximum temperature is maintained in the furnace.

The amount of shrinkage - the amount by which the diameter of the ring has decreased - is measured using a numerical or digital micrometer.

It is recommended to place the rings in multiple places and on different levels of the furnace as this provides the greatest control over the temperature distribution inside the furnace.

The degree of shrinkage of the ring corresponds to the amount of heat absorbed at the point in the furnace where the ring is placed. The diameter can be easily measured using a micrometer.

The letter "T" imprinted on the ring should be placed exactly in the rear sight (measuring notch) of the micrometer.

Both numerical and digital micrometers have an ergonomically designed massive base with a mounting clamp for placing the ring, which ensures that the ring is always properly placed in the micrometer.

This design simplifies the measurement process and improves the repeatability and thus the reliability of measurements.

Packaging:

- 1 piece

UP3D prosthetic scanner UP560 + version with EXOCAD or UPCAD

Super promotion of the EXOCAD version:

- EXOCAD design software for 50% + Exocad Basic training for free! + free Virtual Articulator or Implant module to choose from!:

Make an appointment for a free presentation in your studio/office:

Dental tech. Damian Dunajewski Consultant/CAD/CAM Specialist Tel.600 128 010 damian.dunajewski@mikran.com

Dental tech. Kamil Wolniewicz Consultant/CAD/CAM Specialist Tel.530 596 166 kamil.wolniewicz@mikran.com

The scanner can be purchased in 3 configurations:

- Only with scanning software.

- With EXOCAD scanning and design software for 50% + Exocad Basic training for free! + free Virtual Articulator or Implant module to choose from!

- With scanning software and UPCAD design software.

Ultra-fast scanner with unrivaled accuracy with two 3.0 MP cameras that allow for efficient work and effective scanning:

- Traditional models.

- Split models.

- Models intended for wireframe work (scanning real textures)

- Models with kk (scan body) cartridges.

- Full arch models with implants in one scanning cycle.

- Impressions.

- Models placed in the articulator (Virtual Articulator)

- Models captured in hand-held occlusion

The UP560 scanner is the successor to the UP360+ model. The use of 2 independently operating cameras with a resolution of 3.0 MP and a high number of frames per second allows for faster capture of a much clearer image than cameras in competitive scanners with lower parameters. Placing cameras high above the model at an appropriate angle allows for effective scanning of models and impressions, even with undercuts, without "blind spots" and underscanned elements. The built-in automatic detection of the preparation boundary significantly speeds up the design process.

Parameters:

- Full arc scan: 15s

- Scanning 12 bars: 17s

- Impression scanning: 35s

- All-in-one 21s scanning

- Cameras: Dual 3.0MP (High Frequency)

- Automatic detection of the preparation border

- Accuracy: <6 microns

- Light: blue + multi color

- Interface: USB 3.0

COMMERCIAL INFORMATION/CONTACT:

Mikran.pl ul. Wojskowa 3/L4 60-792 Poznań sklep@mikran.pl, www.mikran.pl

Possibility of free presentation of the scanner in your workshop/office.

Call us: +48 600 128 010 or +48 530 596 166

Silencer (silencer) for Silent lifts

Silent silencer for ski lifts.

Renfert catalog number 29560000

Advantages:

- Up to 50% reduction in perceived suction noise, with constant suction power.

- Quick and easy installation on suction hoses.

- We recommend positioning the muffler vertically to achieve full noise reduction effectiveness.

Packaging:

- 1 piece

Aidite - Sinetring Box

A cuvette with a cover for sintering zirconium crowns and bridges, round, diameter 100 mm.

Packaging:

- 1 piece

Silent compact CAM extractor for milling machines

Compact, bagless extractor for CAM devices used in dentistry

Renfert catalog number 29342000

Advantages:

- Two-way communication between the extractor and the CAM device thanks to the PLC interface

- Optimized suction power in the CAD-CAM device

- Low noise level during operation, max. 55dB(A).

- 3x longer service life compared to conventional collector motors (guaranteed 1000 hours of operation).

- 36-month warranty

Technical data:

- Permissible mains voltage 230–240 V

- Permissible mains frequency 50/60 Hz

- Nominal voltage 230 V

- Power consumption 490 W (230 V)

- Volume flow (max.) 2500 l/min (230 V)

- Max. pressure 219 hPa

- Engine Technology Manifold

- Bagless filtering technology

- Filter quality Class M according to EN 60335-2-69

- CAM interface RJ45 socket

- PLC: input signal 2 x turbine on/off

- PLC: Output signal 2 x status information

- Mains input fuse 8 A

- Number of suction hoses 1

- Sound pressure level (LpA) (at maximum volume flow) 55 dB(A)

- Weight ~13.2 kg

- Dimensions (W x H x D) 245 x 440 x 500 mm

- Ø internal suction connections 35 mm

- Ø external suction connections 40 mm

- Dust container volume ~2.6 l

Packaging:

- Scope of delivery 1X SILENT compactCAM, 230-240 V, 2 m suction hose, 2 mufflers.

P53 Up3D zirconia milling machine - test it for free - call our representative!

Make an appointment for a free presentation in your studio/office:

Dental tech. Damian Dunajewski Consultant/CAD/CAM Specialist Tel.600 128 010 damian.dunajewski@mikran.com

Dental tech. Kamil Wolniewicz Consultant/CAD/CAM Specialist Tel.530 596 166 kamil.wolniewicz@mikran.com

P53, is a new intelligent UP3D dental milling machine, can mill 44 crowns at a time. A fully intelligent machine will help you save 35% of materials.

Functionalities:

- Fully integrated UP3D UPCAM control software, with a lifetime free license and updates, ensures reliable and safe operation of the device and full control over the quality of work performed - the system of automatic continuation of work from the moment it is interrupted at any time allows you to increase efficiency by up to 80%.

- Automatic integrated lift start.

- Tool life sensor.

- 98.5 type disc holder (open system) - standardly built into the machine.

- The half-moon disc holder allows for maximum use of the material and supports milling at an angle of 90 degrees.

- Automatic calibration.

Application:

- Crowns.

- Bridges.

- Foundations.

- Work on implants.

- Complete dentures.

The device mills soft materials:

- Zirconium.

- Wax.

- PEEK.

- PMMA.

- Gypsum.

Product specification:

- Weight 79 kg

- Dimensions 443.5 × 718 × 628.5 cm

- Power 800 W

- Spindle power 520W

- Number of controlled axes 5

- Tool magazine 11 pieces

- Material PEEK, PMMA, Sintermetal, Zirconium oxide (Zr), Wax

- Wet working No

- Spindle speed 60,0000 rpm

- CAD/CAM material storage Manual

- Stepper motor axis drive

- Handle diameter 4 mm

COMMERCIAL INFORMATION/CONTACT:

- Possibility of free presentation of the milling machine in your workshop/office. Call us: +48 600 128 010or +48 530 596 166

Packaging:

- 1 piece

Up3d V10 extractor for P53 milling machine Promotion

Extract V10 FULL DENTAL CAD/CAM SOLUTION.

Advantages:

- The easily removable dust container ensures absolute cleanliness.

- Brushless motor.

- Reduced operating noise ensures a quiet working environment.

- Intelligent connection system with the P53 milling machine.

Technical data:

- Dimensions 240X530X443(mm)

- Weight 20 kg

- Rated voltage 220V±10%

- Rated frequency 50 Hz

- Air volume 2600 l/m

- Air pressure 20KPA

- Filtering 0.3-1um

- Cleaning mode - filter self-cleaning.

- Noise level 70±2

Packaging:

- 1 piece

Silent Power CAM EC extractor for milling machines

The device is an extractor used to extract dust generated in CAM systems used in dentistry. It can be operated manually or controlled by the CAM system. The extractor is equipped with a bidirectional interface used to transmit information about the status of the CAM system and to download control commands from the CAM system. The suction power is fixed and cannot be changed.

Renfert catalog number 29390000

Advantages:

- Reliable production process thanks to brushless EC motor technology (guaranteed operating time 5,000 operating hours).

- Low operating noise level of max. 54.3 dB(A).

- High volume flow of approx. 4000 l/min.

- No additional costs thanks to bagless dust collection.

- 36-month warranty.

Technical data:

- Mains voltage - 230V

- Mains frequency - 50/60 Hz

- Power consumption - 1610 VA

- Mains input fuse - 2x15 A(T)

- Total capacity of the dust container, approx. 7l

- Weight (empty), approx. - 18.0 kg

- Dimensions (Width x Height x Depth) - 270 x 535 x 540 mm

Delivery range:

- 1 SILENT powerCAM EC

- 1 Quick Start Guide

- 3 dust bags (1 piece placed in the dust container)

- 1 Suction hose, 2 m, incl. 2 end connectors.

Renfert-Turbine Silent Compact (extractor motor)

Replacement motor (230V) for Silent Compact and Silent Compact CAM.

Renfert catalog number 900037226

Packaging:

- 1 piece

UGIN e.ON sinter base sintering furnace

The e.ON zirconium sintering furnace is a compact, high-performance furnace. Equipped with 4 heating rods, it is a high-performance stove. Includes automatic door locking to avoid muff damage due to thermal shock. Technical Specifications:

- 7" high resolution color touch screen

- Maximum temperature 1600°C

- Maximum heating rate up to 40°C/minute

- 4 heating elements (rods) in MoSi2 (molybdenum disilicide)

- 1 sintering tray with lid and zircon pearls (capacity up to 20 pieces)

- 40 free programs with 40 possible steps for each program

- Visualization of graphic cycles

- 4 display languages: French, English, Italian, Spanish

- Muff size: 110mm x 110mm x 110mm

- External dimensions (height, width, depth): 540mm x 400mm x 450mm

- Weight: 58 kg

- Maximum power consumption: 1830 kW

- Supply voltage: 230V (50/60 Hz)

Ugin E.ON Sinter Base/Sinter+/Fast+ thermocouple

Thermocouple for the E.ON Sinter Base/Sinter+/Fast+ zirconium sintering furnace

Packaging:

- 1 piece

Ugin Furnace for sintering zirconium e.ON sinter fast

The e.ON sinter fast zirconium oxide sintering furnace from Ugin Dentaire is state-of-the-art equipment and offers exceptional results, such as sintering individual works in just one hour.

40 programs increase the possibilities of long and very short sintering cycles.

Technical Specifications:

- 7 inch (155 mm x 87 mm) high resolution color touch screen

- Cycle time: from one to several hours depending on the zirconia

- Maximum temperature 1750°C

- Temperature accuracy ± 1°C

- Maximum heating rate 65°C/minute

- 1 heating element made of MoSi2 (molybdenum disilicide)

- Dual component thermocouple Platinum/rhodium

- 1 sintering crucible (capacity up to 5 individual units)

- 40 programs with 40 possible steps for each program

- Graphical visualization of the cycle

- 4 display languages: French, English, Italian, Spanish

- Available space (height, diameter): 30mm x 35mm on the crucible

- External dimensions (height, width, depth): 550mm x 330mm x 430mm

- Weight: 29 kg

- Maximum power consumption: 2 kW

- Supply voltage: 230V (50/60 Hz)

Ugin Zirconium sintering furnace e.ON sinter fast +

The e.ON sinter fast + zirconium sintering furnace from Ugin Dentaire presents state-of-the-art equipment and exceptional results, such as sintering in just one hour.

Technical Specifications:

- 7 inch (155 mm x 87 mm) high resolution color touch screen

- Maximum temperature 1730°C

- Operating temperature below 1650°C

- Temperature accuracy ± 1°C

- Cycle time: from one to several hours depending on the zirconia

- Maximum heating rate up to 65°C/minute

- 4 heating elements (rods) in MoSi2 (molybdenum disilicide)

- Dual component thermocouple Platinum/rhodium

- 2 sintering trays with cover and zirconium beads (capacity up to 40 units in conventional cycle and up to 20 units in short cycle)

- 40 programs with 40 possible steps for each program

- Visualization of graphic cycles

- 4 display languages: French, English, Italian, Spanish

- Muff size (height, diameter): 120mm x 110mm

- External dimensions (height, width, depth): 830mm x 420mm x 600mm

- Weight: 74 kg

- Maximum power consumption: 3 kW

- Supply voltage: 230V (50/60 Hz)