Amber Mill Direct HT C14/5 pcs.

Amber Mill Direct is a lithium disilicate block that does not require crystallization.

Advantages:

- Reinforced and aesthetic thanks to graduated translucency.

- Amber Mill Direct can make restorations that only require polishing after milling.

- The translucency of the block can be adjusted by firing the glazed restoration.

- Restorations made from Amber Mill Direct have different microstructures that generate different strengths in the cervical and incisal areas, thus reducing the wear of antagonist teeth.

- Amber Mill Direct achieves natural transparency through the use of a graduated microstructure, from the neck to the incisal/occlusal areas, without additional characterization.

- Strength 355 MPA

Packaging:

- 5 pcs

VOCO Structur CAD - universal block 5 x 40L

CAD/CAM composite for temporaries.

Indications:

- Temporary bridges with up to two spans.

- Temporary crowns with abutment.

- Temporary crowns.

Advantages:

- Quickly and efficiently fabricate precise CAD/CAM temporaries.

- The highest quality and aesthetics ensuring long-term, safe and comfortable use - the product is perfect for long-term and semi-permanent temporary restorations.

- Exceptional margin stability.

- Easy polishing and intra- and extra-oral individualisation.

- Use without MMA primer.

Packaging:

- 5pc/1pack

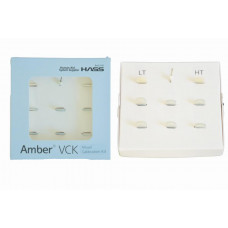

Amber Mill C12 / 5pcs PROMOTION

Amber Mill is the first lithium disilicate glass-ceramic with the ability to regulate translucency by temperature and crystallization time (HT / MT / LT / MO).

Benefits:

It is characterized by unrivaled mechanical properties, easy processing and high aesthetic values.

Strength after crystallization 450MPa

Translucency is dependent on the time of crystallization.

Attention:

- For processing and polishing, we recommend the Diadur / Diapro stone and rubber set, code mikran 2251

Package:

- 5 pcs / 1 box

IPS Empress CAD for Cerec/InLab LT I 12/5pcs

Leucite-reinforced glass-ceramic blocks consisting of a glassy and a crystalline phase. They are used to perform an extremely aesthetic, completely anatomical reconstruction of a single tooth, using CAD/CAM technology in the Cerec system and in the laboratory system. Due to the difference in thermal expansion coefficients (CTE) between the glass phase and the crystal phase (leucite), compressive stresses in the glass phase arise during cooling after sintering. This mechanism increases strength, giving IPS Empress CAD a flexural strength of 160 MPa

Advantages:

- Good fit accuracy;

- homogeneous surface;

- high strength;

- Exact color match with the shade guide.

Technical properties:

- CTE (100- 400°C) [10-6-K]CTE} - 16.6

- CTE (100- 500°C) [10- 6K] - 17.5

- Bending strength (biaxial) - 160

- Crack resistance [MPa m0.5] - 1.3

- Vickers hardness - 6200

- Chemical solubility [ug/cm2] - 25

Indications:

- Anterior and lateral crowns

- Partial crowns

- Veneers

IPS Empress CAD LT (Low Translucency) LT blocks are available in 9 of the most popular AD scale shades and 4 shades for teeth after bleaching Bleach BL. Thanks to their high brightness, higher than in the case of HT blocks, they are ideal for making larger restorations (e.g. anterior and posterior crowns. Restorations made of LT blocks are characterized by a natural degree of brightness and chromaticity. This prevents the gray effect of embedded restorations. These blocks have a natural fluorescence that allows the restoration to match the rest of the teeth naturally in different lighting conditions. LT blocks are ideal for working with the cut back technique.

Dimensions I 12:

- Width: 10.0mm

- Length: 12.0mm

- Height: 15.0mm

Packaging:

1 package/5pcs

IPS Empress CAD for CEREC/inLab LT C14/5pcs

Leucite-reinforced glass-ceramic blocks consisting of a glassy and a crystalline phase. They are used to perform an extremely aesthetic, completely anatomical reconstruction of a single tooth, using CAD/CAM technology in the Cerec system and in the laboratory system. Due to the difference in thermal expansion coefficients (CTE) between the glass phase and the crystal phase (leucite), compressive stresses in the glass phase arise during cooling after sintering. This mechanism increases strength, giving IPS Empress CAD a flexural strength of 160 MPa

Advantages:

- Good fit accuracy;

- homogeneous surface;

- high strength;

- Exact color match with the shade guide.

Technical properties:

- CTE (100- 400°C) [10-6-K]CTE} - 16.6

- CTE (100- 500°C) [10- 6K] - 17.5

- Bending strength (biaxial) - 160

- Crack resistance [MPa m0.5] - 1.3

- Vickers hardness - 6200

- Chemical solubility [ug/cm2] - 25

Indications:

- Anterior and lateral crowns

- Partial crowns

- Veneers

IPS Empress CAD LT (Low Translucency) LT blocks are available in the 9 most popular AD scale shades and 4 shades for teeth after bleaching Bleach BL. Thanks to their high brightness, higher than in the case of HT blocks, they are ideal for making larger restorations (e.g. anterior and posterior crowns. Restorations made of LT blocks are characterized by a natural degree of brightness and chromaticity. This prevents the gray effect of embedded restorations. These blocks have a natural fluorescence that allows the restoration to match the rest of the teeth naturally in different lighting conditions. LT blocks are ideal for working with the cut back technique.

Dimensions C14:

- Width: 12.0mm

- Length: 14.0mm

- Height: 18.0mm

Packaging:

- 1 package/5pcs

IPS Empress CAD for Cerec/InLab Multi I12 /5pcs

Leucite-reinforced glass-ceramic blocks consisting of a glassy and a crystalline phase. They are used to perform an extremely aesthetic, completely anatomical reconstruction of a single tooth, using CAD/CAM technology in the Cerec system and in the laboratory system. Due to the difference in thermal expansion coefficients (CTE) between the glass phase and the crystal phase (leucite), compressive stresses in the glass phase arise during cooling after sintering. This mechanism increases strength, giving IPS Empress CAD a flexural strength of 160 MPa

Advantages:

- Good fit accuracy;

- homogeneous surface;

- high strength;

- Exact color match with the shade guide.

Technical properties:

- CTE (100- 400°C) [10-6-K]CTE} - 16.6

- CTE (100- 500°C) [10- 6K] - 17.5

- Bending strength (biaxial) - 160

- Crack resistance [MPa m0.5] - 1.3

- Vickers hardness - 6200

- Chemical solubility [ug/cm2] - 25

Indications:

- Anterior and lateral crowns

- Partial crowns

- Veneers

IPS Empress CAD Multi:

The blocks are available in the 5 most popular colors of the AD scale and in 3 sizes. Thanks to the natural shade distribution from the dentine to the incisal materials, restorations made of Multi IPS Empress CAD blocks ensure maximum aesthetics and naturalness. The natural arrangement of opaque and transparent layers allows for different aesthetics. The IPS Empress CAD Multi block is characterized by a natural fluorescence pattern similar to the natural tooth, which allows the restoration to be perfectly matched to the natural teeth. Thanks to the innovative combination of natural color scheme, translucency and fluorescence, very aesthetic restorations are created in the simplest way.

Dimensions I 12:

- Width: 10.0mm

- Length: 12.0mm

- Height: 15.0mm

Packaging:

1pack/5pcs

IPS e.max CAD for Cerec/inLab LT I12/5pcs

IPS e.max CAD are lithium disilicate glass ceramic blocks for CAD/CAM technology. The manufacturing process guarantees completely homogeneous blocks. The pre-crystallized (blue) block can be easily developed in a CAD/CAM device. The block in the pre-crystallized state has a characteristic white color that goes through a blue shade to a blue-gray tone. This color depends on the composition and structure of the glass ceramics. The strength of the material in this state is 130-150 MPa and is thus comparable to other glass ceramic blocks currently available on the market. After the restoration has been cut out of the blocks, it is crystallized in the Ivoclar Vivadent ceramic furnace (e.g. Programat CS). The crystallization process is easy to carry out and, unlike other CAD/CAM systems, restorations made in this way do not shrink and do not require a time-consuming infiltration process, and the whole process takes about 20-25 minutes. Crystallization at 840 °C causes changes in the structure of the ceramics, followed by the growth of lithium disilicate crystals. The resulting densification of 0.2% is already predicted in the CAD software and taken into account when cutting the restoration. Thanks to changes in the structure, the strength of the material increases to 360 MPa and it obtains the appropriate optical properties.

IPS e.max CAD blocks are characterized by natural brightness. Thanks to the translucency and variety of shades, fully anatomical restorations can be easily fabricated with this glass ceramic.

Indications:

Veneers

inlay

Onlay

Partial crowns

Anterior and lateral crowns

Implant superstructures for single restorations (anterior and lateral sections)

Dimensions I 12 :

Width: 10.0mm

Length: 12.0mm

Height: 15.0mm

Packaging:

5 pcs

IPS e.max CAD for Cerec/InLab LT C14/ 5 pcs

IPS e.max CAD are lithium disilicate glass ceramic blocks for CAD/CAM technology. The manufacturing process guarantees completely homogeneous blocks. The pre-crystallized (blue) block can be easily developed in a CAD/CAM device. The block in the pre-crystallized state has a characteristic white color that goes through a blue shade to a blue-gray tone. This color depends on the composition and structure of the glass ceramics. The strength of the material in this state is 130-150 MPa and is thus comparable to other glass ceramic blocks currently available on the market. After the restoration has been cut out of the blocks, it is crystallized in the Ivoclar Vivadent ceramic furnace (e.g. Programat CS). The crystallization process is easy to carry out and, unlike other CAD/CAM systems, restorations made in this way do not shrink and do not require a time-consuming infiltration process, and the entire process takes about 20-25 minutes. Crystallization at 840 °C causes changes in the structure of the ceramics, followed by the growth of lithium disilicate crystals. The resulting densification of 0.2% is already predicted in the CAD software and taken into account when cutting the restoration. Thanks to changes in the structure, the strength of the material increases to 360 MPa and it obtains the appropriate optical properties.

IPS e.max CAD blocks are characterized by natural brightness. Thanks to the translucency and variety of shades, fully anatomical restorations can be easily fabricated with this glass ceramic.

Indications:

Veneers

inlay

Onlay

Partial crowns

Anterior and lateral crowns

Implant superstructures for single restorations (anterior and lateral sections)

Dimensions C14:

Width: 12.4mm

Length: 14.5mm

Height: 18.0mm

Packaging:

5 pcs

IPS Empress CAD for Cerec/InLab Multi C14/5pcs

Leucite-reinforced glass-ceramic blocks consisting of a glassy and a crystalline phase. They are used to perform an extremely aesthetic, completely anatomical reconstruction of a single tooth, using CAD/CAM technology in the Cerec system and in the laboratory system. Due to the difference in thermal expansion coefficients (CTE) between the glass phase and the crystal phase (leucite), compressive stresses in the glass phase arise during cooling after sintering. This mechanism increases strength, giving IPS Empress CAD a flexural strength of 160 MPa

Advantages:

- Good fit accuracy;

- homogeneous surface;

- high strength;

- Exact color match with the shade guide.

Technical properties:

- CTE (100-400°C) [10-6-K]CTE} - 16.6

- CTE (100-500°C) [10-6K] - 17.5

- Bending strength (biaxial) - 160

- Crack resistance [MPa m0.5] - 1.3

- Vickers hardness - 6200

- Chemical solubility [ug/cm2] - 25

Indications:

- anterior and posterior crowns

- partial crowns

- school

IPS Empress CAD Multi:

- The blocks are available in the 5 most popular colors of the AD scale and in 3 sizes. Thanks to the natural shade distribution from the dentine to the incisal materials, restorations made of Multi IPS Empress CAD blocks ensure maximum aesthetics and naturalness. The natural arrangement of opaque and transparent layers allows for different aesthetics. The IPS Empress CAD Multi block is characterized by a natural fluorescence pattern similar to the natural tooth, which allows the restoration to be perfectly matched to the natural teeth. Thanks to the innovative combination of natural color scheme, translucency and fluorescence, very aesthetic restorations are created in the simplest way.

Dimensions C14:

- Width: 12.0mm

- Length: 14.0mm

- Height: 18.0mm

Packaging:

- 1pack/5pcs

IPS e.max CAD for Cerec/inLab HT I12/5pcs

High translucency lithium disilicon ceramic blocks.

IPS e.max CAD are lithium disilicate glass ceramic blocks for CAD/CAM technology. The manufacturing process guarantees completely homogeneous blocks. The pre-crystallized (blue) block can be easily developed in a CAD/CAM device. The block in the pre-crystallized state has a characteristic white color that goes through a blue shade to a blue-gray tone. This color depends on the composition and structure of the glass ceramics. The strength of the material in this state is 130-150 MPa and is thus comparable to other glass ceramic blocks currently available on the market. After the restoration has been cut out of the blocks, it is crystallized in the Ivoclar Vivadent ceramic furnace (e.g. Programat CS). The crystallization process is easy to carry out and, unlike other CAD/CAM systems, restorations made in this way do not shrink and do not require a time-consuming infiltration process, and the entire process takes about 20-25 minutes. Crystallization at 840 °C causes changes in the structure of the ceramics, followed by the growth of lithium disilicate crystals. The resulting densification of 0.2% is already predicted in the CAD software and taken into account when cutting the restoration. Thanks to changes in the structure, the strength of the material increases to 360 MPa and it obtains the appropriate optical properties. IPS e.max CAD blocks are naturally bright. Thanks to the translucency and variety of shades, fully anatomical restorations can be easily fabricated with this glass ceramic.

Application:

Veneers

Inlay

Onlay

Partial crowns

Dimensions I 12:

- Width: 10.0mm

- Length: 12.0mm

- Height: 15.0mm

Packaging:

- 5pcs/pack

IPS e.max CAD for Cerec/inLab HT C14/5pcs

High translucency lithium disilicon ceramic blocks.

IPS e.max CAD are lithium disilicate glass ceramic blocks for CAD/CAM technology. The manufacturing process guarantees completely homogeneous blocks. The pre-crystallized (blue) block can be easily developed in a CAD/CAM device. The block in the pre-crystallized state has a characteristic white color that goes through a blue shade to a blue-gray tone. This color depends on the composition and structure of the glass ceramics. The strength of the material in this state is 130-150 MPa and is thus comparable to other glass ceramic blocks currently available on the market. After the restoration has been cut out of the blocks, it is crystallized in the Ivoclar Vivadent ceramic furnace (e.g. Programat CS). The crystallization process is easy to carry out and, unlike other CAD/CAM systems, restorations made in this way do not shrink and do not require a time-consuming infiltration process, and the whole process takes about 20-25 minutes. Crystallization at 840 °C causes changes in the structure of the ceramics, followed by the growth of lithium disilicate crystals. The resulting densification of 0.2% is already predicted in the CAD software and taken into account when cutting the restoration. Thanks to changes in the structure, the strength of the material increases to 360 MPa and it obtains the appropriate optical properties. IPS e.max CAD blocks are naturally bright. Thanks to the translucency and variety of shades, fully anatomical restorations can be easily fabricated with this glass ceramic.

Application:

Veneers

Inlay

Onlay

Partial crowns

Dimensions C 14:

- Width: 12.4mm

- Length: 14.5mm

- Height: 18.0mm

Packaging:

- 5pcs/pack

IPS e.max CAD for CEREC/inLab LT B32/3pcs

PS e.max CAD are lithium disilicate glass ceramic blocks for CAD/CAM technology. The manufacturing process guarantees completely homogeneous blocks. The pre-crystallized (blue) block can be easily developed in a CAD/CAM device. The block in the pre-crystallized state has a characteristic white color that goes through a blue shade to a blue-gray tone. This color depends on the composition and structure of the glass ceramics. The strength of the material in this state is 130-150 MPa and is thus comparable to other glass ceramic blocks currently available on the market. After the restoration has been cut out of the blocks, it is crystallized in the Ivoclar Vivadent ceramic furnace (e.g. Programat CS). The crystallization process is easy to carry out and, unlike other CAD/CAM systems, restorations made in this way do not shrink and do not require a time-consuming infiltration process, and the entire process takes about 20-25 minutes. Crystallization at 840 °C causes changes in the structure of the ceramics, followed by the growth of lithium disilicate crystals. The resulting densification of 0.2% is already predicted in the CAD software and taken into account when cutting the restoration. Thanks to changes in the structure, the strength of the material increases to 360 MPa and it obtains the appropriate optical properties. IPS e.max CAD blocks are naturally bright. Thanks to the translucency and variety of shades, fully anatomical restorations can be easily fabricated with this glass ceramic.

Indications:

Veneers

inlay

Onlay

Partial crowns

Anterior and lateral crowns

Implant superstructures for single restorations (anterior and lateral sections)

Dimensions:

Width: 14.5mm

Length: 14.5mm

Height: 32.0 mm

Packaging:

3pcs

IPS e.max CAD for CEREC/inLab MT C14/5pcs

Medium translucency lithium disilicon ceramic blocks.

IPS e.max CAD are lithium disilicate glass ceramic blocks for CAD/CAM technology. The manufacturing process guarantees completely homogeneous blocks. The pre-crystallized (blue) block can be easily developed in a CAD/CAM device. The block in the pre-crystallized state has a characteristic white color that goes through a blue shade to a blue-gray tone. This color depends on the composition and structure of the glass ceramics. The strength of the material in this state is 130-150 MPa and is thus comparable to other glass ceramic blocks currently available on the market. After the restoration has been cut out of the blocks, it is crystallized in the Ivoclar Vivadent ceramic furnace (e.g. Programat CS). The crystallization process is easy to carry out and, unlike other CAD/CAM systems, restorations made in this way do not shrink and do not require a time-consuming infiltration process, and the entire process takes about 20-25 minutes. Crystallization at 840 °C causes changes in the structure of the ceramics, followed by the growth of lithium disilicate crystals. The resulting densification of 0.2% is already predicted in the CAD software and taken into account when cutting the restoration. Thanks to changes in the structure, the strength of the material increases to 360 MPa and it obtains the appropriate optical properties. IPS e.max CAD blocks are naturally bright. Thanks to the translucency and variety of shades, fully anatomical restorations can be easily fabricated with this glass ceramic.

Application:

Inputs

Veneers

Thin veneers

Partial crowns

Anterior and lateral crowns

Packaging:

- 5pcs/pack

IPS e.max CAD for CEREC/inLab MO C14/5pcs

PS e.max CAD are lithium disilicate glass ceramic blocks for CAD/CAM technology. The manufacturing process guarantees completely homogeneous blocks. The pre-crystallized (blue) block can be easily developed in a CAD/CAM device. The block in the pre-crystallized state has a characteristic white color that goes through a blue shade to a blue-gray tone. This color depends on the composition and structure of the glass ceramics. The strength of the material in this state is 130-150 MPa and is thus comparable to other glass ceramic blocks currently available on the market. After the restoration has been cut out of the blocks, it is crystallized in the Ivoclar Vivadent ceramic furnace (e.g. Programat CS). The crystallization process is easy to carry out and, unlike other CAD/CAM systems, restorations made in this way do not shrink and do not require a time-consuming infiltration process, and the entire process takes about 20-25 minutes. Crystallization at 840 °C causes changes in the structure of the ceramics, followed by the growth of lithium disilicate crystals. The resulting densification of 0.2% is already predicted in the CAD software and taken into account when cutting the restoration. Thanks to changes in the structure, the strength of the material increases to 360 MPa and it obtains the appropriate optical properties. IPS e.max CAD blocks are naturally bright. Thanks to the translucency and variety of shades, fully anatomical restorations can be easily fabricated with this glass ceramic.

Application:

- Blocks of medium opacity characterized by ideal properties to hide discoloration of pillars. Particularly indicated for the fabrication of frameworks in a reduced anatomical shape intended for veneering and implant-supported restorations.

Dimensions C 14:

Width 12.4mm

Length 14.5mm

Height 18mm

Packaging:

5pcs/pack

Amber Mill C14 /5pcs PROMOTION

Amber Mill is the first lithium disilicate glass-ceramic material with adjustable translucency through temperature and crystallization time (HT/MT/LT/MO).

Advantages:

It is characterized by unrivaled mechanical properties, easy processing and high aesthetic values.

Strength after crystallization 450MPa

Translucency is dependent on crystallization time.

Attention:

- For processing and polishing, we recommend a set of Diadur/Diapro stones and erasers, code mikran 2251

Packaging:

- 5pcs

Amber Mill C32/3pcs

Amber Mill is the first lithium disilicate glass-ceramic material with adjustable translucency through temperature and crystallization time (HT/MT/LT/MO).

It is characterized by unrivaled mechanical properties, easy processing and high aesthetic values.

Strength after crystallization 450MPa

Translucency is dependent on crystallization time.

Attention:

- For processing and polishing, we recommend a set of Diadur/Diapro stones and erasers, code mikran 2251

Packaging:

- 3pcs

Amber Mill C40/3pcs

Amber Mill is the first lithium disilicate glass-ceramic material with adjustable translucency through temperature and crystallization time (HT/MT/LT/MO).

It is characterized by unrivaled mechanical properties, easy processing and high aesthetic values.

Strength after crystallization 450MPa

Translucency is dependent on crystallization time.

Attention:

- For processing and polishing, we recommend a set of Diadur/Diapro stones and erasers, code mikran 2251

Packaging:

- 3pcs

Tetric CAD for CEREC/inLab HT C14/5pcs

Highly translucent composite blocks for highly esthetic single restorations. Class IIa medical products.

Size:

- 11.8 x 13.8 x 17.8mm

Advantages:

- Integration of the restoration with the natural dentition in the mouth thanks to the unique “chameleon effect”

- Polishes very well, can be repaired inside the mouth.

- Stable seating thanks to the coordinated cementation system.

- Durable and durable prosthetic restoration even with minimal wall thicknesses.

Indications:

- Veneers.

- inlay.

- Onlays (e.g. occlusal veneers, partial crowns)

- Anterior and lateral crowns.

Physical data:

- Bending strength (biaxial) minimum 100 MPa.

- Average value 272 MPa.

- Water absorption 21 µg/mm³.

- Solubility 0.0 µg/mm³.

Packaging:

- 1pack/5pcs

Tetric CAD for CEREC/InLab MT C14/5pcs

Medium translucency composite blocks for highly esthetic single restorations.

Size:

- 12.4 x 14.5 x 18mm

Advantages:

- Integration of the restoration with the natural dentition in the mouth thanks to the unique “chameleon effect”

- Easy to finish and shine, and can be repaired inside the mouth.

- Stable seating thanks to the coordinated cementation system.

- Durable and durable prosthetic restoration even with minimal wall thicknesses.

Indications:

- Veneers.

- inlay.

- Onlays (e.g. occlusal veneers, partial crowns)

- Anterior and lateral crowns.

Packaging:

- 1pack/5pcs

Tetric CAD for PrograMill HT C14/5pcs

Aesthetic composite block for the production of indirect single-tooth restorations.

Advantages:

- Thanks to the pronounced chameleon effect, the restorations blend optically into the tooth structure.

- After grinding, the restoration is polished and adhesively bonded.

- Quick and easy process.

Packaging:

- 1pack/5pcs

Tetric CAD for PrograMill MT C14/5pcs

Aesthetic composite block for the production of indirect single-tooth restorations.

Advantages:

- Thanks to the pronounced chameleon effect, the restorations blend optically into the tooth structure.

- After grinding, the restoration is polished and adhesively bonded.

- Quick and easy process.

Packaging:

- 1pack/5pcs

IPS e.max CAD for PrograMill HT C14/5

Lithium disilicate glass ceramic. IPS e.max CAD is the world's best-selling glass ceramic. It is suitable for the efficient fabrication of full contour restorations and is known for its versatile applications, wide range of processing options and high strength of 530 MPa.

Packaging:

- 1pack/5pcs

IPS e.max CAD for PrograMill MT C14/5

Lithium disilicate glass ceramic. IPS e.max CAD is the world's best-selling glass ceramic. It is suitable for the efficient fabrication of full contour restorations and is known for its versatile applications, wide range of processing options and high strength of 530 MPa.

Packaging:

- 1pack/5pcs

IPS e.max CAD for PrograMill HT I12/5

Lithium disilicate glass ceramic. IPS e.max CAD is the world's best-selling glass ceramic. It is suitable for the efficient fabrication of full contour restorations and is known for its versatile applications, wide range of processing options and high strength of 530 MPa.

Packaging:

- 1pack/5pcs